Abstract

Quantitation of paint powders of ancient wall paintings is often hindered by the calcite contamination during samples withdrawal. To overcome this problem, a new approach was explored based on the mechanical pulverization of the paint powder followed by the evaluation of its true concentration, namely binders, pigments, and decaying compounds, from the comparison of the calcite FT-IR peak area at 2510 cm−1 with that of the corresponding underlying calcite used as calibrator. After extraction of the pulverized paint powder with polar and nonpolar solvents, liquid chromatography, gas chromatography with flame ionization detection, and gas chromatography–mass spectrometry were used to estimate the free amino acids, and fatty acids profiles. Compared to our previous investigation, the results obtained showed a better yield of the extracted organic materials as mg/kg of powder and also a qualitative improvement of the lipids profile.

Similar content being viewed by others

Introduction

The house of Golden Bracelet, Insula Occidentalis, was first explored in the Bourbon period between 1758 and 1763 while the systematic excavation began in the 70s. Dating between 35 and 40 A.D., the paintings testify a redecoration of the house in the 4th style, executed after the restoration of the damages caused by the earthquake of 62 A.D. This hypothesis was supported by the discovery in 1983, during excavation of the garden of a large quantity of painted fragment belonging to a previous decoration of an environment of the upper floors. The restorers of Pompeii’s Affreschi Restoration Laboratory used these fragments to partly reconstruct a fine painting of the 3rd style [1]. Consequently, most of the wall paintings ruin stored in the house were likely belonging to the third style period (from the end of the first century B.C. to about half of the first century A.D.). Under this aspect, the analysis of these ancient paintings composition represents a very stimulating mission that involves expertise in analytical techniques. However, besides the millenarian age and the effects of weathering and external agents (chemical, and biological), it appears very difficult to know in general the exact original composition of ancient Roman wall painting mixtures [2]. Nevertheless, the study of ancient paintings represents a challenge for the choice of appropriate valorization and conservation interventions [3, 4]. One criticism concerning the chemical analyses of ancient Roman mural painting regards the use of an efficient procedure for the extraction of painting components and in particular those of organic nature. In fact, most Roman compositions have been classified as fresco since the lack of an accurate analysis of the original painting mixture. Moreover, Roman wall painting analyses carried out by several research groups showed repetitive results that were abnormally different between each group [5]. These differences most likely can be ascribed to factors affecting the extraction methods of paint media adopted as well as to their history. Therefore, the characterization of the binder composition can be affected by a scarce efficiency of extraction methods that might not unveil some binder components. All these aspects prompted us to set up an extraction method based on the mechanical pulverization of the scraped wall paint powder followed by its quantitation based on the FT-IR comparative analysis of a calcite peak of the paint powder layer with that of the corresponding underlying calcite layer as calibrator. Liquid chromatography, gas chromatography (GC) with flame ionization detection and gas chromatography–mass spectrometry (GC–MS) was used to analyze the polar and non-polar binder compositions of sporadic wall painting samples. The results obtained were compared with our previous work carried on Pompeian’s wall paintings from Insula Occidentalis [6, 7].

Materials and methods

Materials and reagents

Analytical high-performance liquid chromatography (HPLC) solvents, including methanol, ethanol, chloroform, hexane, and dichloromethane were obtained from JT Baker (Deventer, Netherlands). Hydrochloric acid 37% was purchased from Carlo Erba (Cornaredo, Italy). Ammonium bicarbonate was purchased from Merck (Merck KGaA, Darmstadt, Germany). Amino acid calibration standards in 0.1 mol/L HCl, borate buffer 0.4 mol/L in water (pH 10.2), and 10 mg/mL o-phthalaldehyde- 3-mercaptopropionic acid (OPA-3-MPA) reagent in borate buffer (0.4 mol/L) were obtained from Agilent Technologies GmbH & Co.KG (Waldbronn, Germany). Dithiothreitol (DTT) was purchased from Sigma Aldrich (St. Louis, MO, USA). The pentadecanoic acid (C15:0, Sigma, St. Louis, MO, USA) was dissolved in ethanol at a final concentration of 0.2 mg/mL. Boron trifluoride/methanol (10%, w/w) was purchased from Supelco (Bellefonte, PA, USA).

Wall painting samples and sampling step preparation

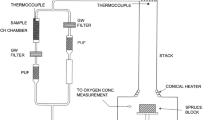

Five sporadic wall painting samples were selected from a large collection of archaeological ruins stored in Pompeii’s house of Golden Bracelet, Insula Occidentalis. The specimens (about 5 × 3 × 2 cm, see Fig. 1) were carefully handled to prevent further contamination and gently cleaned with a soft brush and wet bibula paper to remove dust deposit. All samples surface did not show the presence of any evident patina not belonging to the painting layer. The first sample was mostly of a grey color with brown decoration, the second contained intense red and green coloration, the third showed green decoration on a yellowish background, the fourth showed light green violet and orange colors, and the fifth was made of weak red color. For chemical analyses, amounts of wall painting powder ranging between 60 and 130 mg were scraped with a new disposable scalpel from sample surface whereas amounts between 50 and 130 mg were scraped from the below corresponding remaining calcite layer. Powders were suspended in distilled water up to a concentration of 200 mg/mL and then mechanically pulverized on ice for 5 min at half maximum speed by using an Ultra Turrax T25 Digital Homogenizer (IKA®-Werke GmbH & Co. KG, Staufen, Germany). The extraction of polar and nonpolar compounds was carried out according to the method of the Standard Metabolic Reporting Structures working group [8].

FT-IR spectroscopy

Samples (200 mg/mL) were diluted at different concentration of 10, 5 and 2.5 μg/μL. 3 μL of each suspension (corresponding to 30, 15 and 7.5 μg) was layered on 3 mm ZnS window, dried under a white lamp (60 watts) and analyzed with a Nicolet 5700 equipped with a microscope ContinuμM (Thermo Fisher Scientific, Waltham, MA). For each sample, 3 spectra (200 acquisitions) in transmission mode were collected, with a sensitivity of eight, and the microscope focusing windows set at 100 × 100 μm. Peak areas were then evaluated by using the Omnic software (Thermo Fisher Scientific).

Evaluation of oxalate was performed by FT-IR in the spectral region between 690 and 890 cm−1, by measuring for each sample the peak area at around 780 cm−1. Using the OriginPro 7.5 software spectra deconvolution and curve fitting was performed. Peak assignment was evaluated on the basis of the data library [9].

Amino acid and protein analysis

An aliquot of each wall painting samples corresponding to 10 mg of powder was dried under nitrogen and suspended in 100 μL of 50 mM ammonium bicarbonate, sonicated for 10 min, vortexed and centrifuged at 14,000 rpm for 10 min. The supernatants were collected and subjected to pre-column derivatization in the needle of the autosampler with OPA-3-MPA, and injected in the HPLC system as previously reported [10]. Briefly, each sample (25 μL) was transferred into a conical vial insert for pre-column derivatization, and the amino acid concentration was determined using the calibration curve. Amino acids were identified and quantified by comparison of their retention time and absorption ratio with those of authentic compounds in the calibration solution containing 25 amino acids (Asp, Glu, Asa, Asn, Ser, Glx, His, Gly, Thr, Cit, Arg, Ala, Tau, Tyr, Val, Met, Trp, Phe, Ile, Orn, Leu, Lys, Oxo-Pro, Sarc, Pro) and norvaline as internal standard. The analyses were performed using an Agilent Technologies 1200 Series LC System (Agilent, Santa Clara, CA) equipped with a binary pump delivery system, an autosampler to automate the pre-column derivatization and injection procedure, a heated column compartment, and a programmable fluorescence detector. All of the equipment was controlled by Agilent ChemStation software. An Agilent Zorbax Eclipse XDB-C18 analytical column (5 μm, 4.6 × 150 mm), was used in parallel to an Agilent Eclipse XDB-C18 analytical Guard column (5 μm, 4.6 × 12.5 mm) for chromatographic separations.

For the analysis of proteins, 50 μL of the ammonium bicarbonate supernatant was also incubated in 5.8 mM dithiothreitol (DTT) for 5 min at 95 °C for disulfide bridges reduction and analyzed according to the procedure described by Chambery et al. [11].

Lipid analysis

An aliquot of each wall painting samples corresponding to 50 mg of powder was dried under nitrogen and C15:0 (10 μg) was added to each powder as an internal standard. Methanol (800 μL) and water (170 μL) were added and the samples were vortex for 3 min. Then, chloroform (400 μL) was added, and the samples were incubated on ice for 10 min. Finally, chloroform (400 μL) and water (400 μL) were added to the samples and, after vortex mixing for 3 min, the samples were centrifuged at 3000 rpm for 30 min. The lower layer (lipophilic phase) was filtered by glass microfiber filter, dried under a stream of nitrogen, and re-suspended in 500 μL of BF3/methanol (10%, w/w). Trans-esterification of complex lipids was performed at 60 °C for 20 min. Then, the sample was mixed with 1 mL of distilled water and the methylated fatty acids were extracted two times with 1 mL of hexane. The samples were dried under a gentle nitrogen stream and the residue was dissolved in 100 μL of CH2Cl2. Aliquots (1 μL) of the samples were analyzed by GC-FID (HP-5890, Agilent) and GC–MS (GC 8000/MD800, Fisons Instruments) controlled by a workstation equipped with MassLab 3.4 software [7].

Results

Wall paintings specimens collected from the Pompeii’s House of Golden Bracelet are shown in Fig. 1. Before the analyses of the paint powders, it was first evaluated the effective amount of paint components present in each sample. The quantitation was performed by FT-IR spectroscopy comparing a calcite peak area present in the sample paint stratum with that of the corresponding underlying calcite used as calibrator. The calcite wavenumber selected, 2510 cm−1 (CaCO3 FT-IR spectra, Fig. 2, inset a), was chosen because it occurred in a spectral region where no overlapping with other infrared signals from chemical compounds present in the samples. The amount of paint powder and that of the corresponding underlying calcite scraped from each sample is reported in Table 1. After mechanical treatment, for each painting sample and for the corresponding underlying calcite, FT-IR peak areas were measured at increasing amounts of material (7.5, 15, and 30 μg) deposited on ZnS window. Figure 2 shows the representative FT-IR spectra of paint and calcite layers. Peak areas were then plotted for calculation. Figure 3 shows the representative result obtained for sample S3. On the basis of the plot equations of the calcite used as the calibrator, it was calculated the amount of calcite present in each paint powder (Table 2). From the average of the three values of each sample (S1–S5), it was calculated the percentage of true paint present in each scraped painting sample (constituted most likely of binders, pigments, and decaying compounds) and the percentage of corresponding calcite (Table 2). The different true paint values can be most likely ascribed to the fact that they are coming from different ruins stored in the house of Golden Bracelet, Insula Occidentalis.

Representative FT-IR spectra of paint powder layer and underlying calcite layer. Spectra of sample S3 (upper panel) and corresponding calcite layer (lower panel) collected from a 30 μg spot. The area of the calcite peak at 2510 cm−1 (2400–2700 cm−1) was used for sample components quantitation. Inset, calcium carbonate FT-IR spectra frequencies

FT-IR peak area (2510 cm−1) at increasing sample amounts (sample S3). For each sample spot deposited on ZnSe window, four spectra were collected and the average peak area, SE and curve equation was calculated. (Filled square) Underlying calcite layer of sample S3; (filled diamond) Paint layer of sample S3. SE, standard error

To assess the bio-deterioration and/or deterioration of each painting samples, it was checked by FT-IR spectroscopy the possible presence of calcium oxalate. Calcium oxalate (whewellite and weddellite) show characteristic absorption peak at around 1622, 1319 and 779 cm−1 for monohydrate [12], and at around 1643, 1330 and 783 cm−1 for the dehydrate [13]. Using OriginPro software, we analyzed the 690–890 cm−1 region where spectra deconvolution and peak fitting gave better results. The average peak area/μg at 780 cm−1 of each sample is reported in Table 2.

The free amino acid concentrations determined in the five samples, expressed as mg/kg of powder and as percentages, are reported in Table 3. The total amino acid concentration detected in all samples ranged from 1764 to 7592 mg/kg of paint. These results were about two orders of magnitude higher than those reported in previous works (values ranging from 5.13 [7] to 28.91 [6]). Samples S1 and S5 showed a total amino acid concentration at least 2.9 times higher than those of samples S2, S3, and S4. Furthermore, the most abundant amino acid in samples S1 and S5 was glycine with a percentage of 43.6% and 38.5%, respectively. These data were also in agreement with the free amino acids profiles detected in a previous study [7] and could be indicative of collagen (animal glue), a protein characterized by the presence of a high content of glycine, proline, and hydroxyproline [14]. Instead, in samples S2, S3, and S4, ornithine was the most abundant amino acid with a percentage ranging between 20.4% and 27.8%. The highest percentage of the not proteinogenic ornithine could be due to the presence in the painting mixture of components of animal or vegetal origin [15] or might derive from the conversion of arginine [16]. Regarding the characterization of proteins, a shotgun LC–MS/MS analysis was executed on the tryptic paint powder digest. In this instance, no proteinaceous material was detected in all samples. This result was also confirmed by SDS-PAGE followed by Coomassie Blue staining (data not shown). Overall, these results suggested that the painting mixture of samples S1 and S5 contained probably similar organic components that were different from those used for the preparation of the painting mixture of samples S2, S3, and S4.

The analysis of non-polar fractions allowed the identification of nine fatty acids (Fig. 4 and Table 4). These were identified as C12:0, C14:0, C16:1, C16:0, C17:0, C18:2, cis-C18:1, trans-C18:1, and C18:0. Minor peaks of unidentified compounds were not taken into consideration for calculations. The total amount of fatty acids ranged from 649 to 1630 mg/Kg. Compared to previous analyses (values ranging from 63.78 to 509.78 mg/Kg), these values were on average one order of magnitude higher [7]. The lipid contents resulted quite similar among the five samples, with C16:0, cis-C18:1, and C18:0 being the most abundant (average 41, 14, and 31%, respectively). The ratio of C16:0/C18:0, used to distinguish animal fats from plant oils [17], was in all samples > 1 thus indicating the possible presence of fat of animal origin [18, 19] or a mix of different type of fats (animal or vegetal). However, in the work of Evershed et al. [20] it is reported a C16/C18 value < 1 in the case of the animal sample like the lamp, and > 2 in the case of dripping dishes. Therefore, the identification of the origin of the fats or indicating if they are mixtures of fats is not straightforward [20]. These figures were similar to those reported in our previous study on Pompeian’s wall paintings [6, 7] but differ from that found in the sample from Liternum where more components of animal origin were present [21]. The other lipids C12:0, C14:0, C16:1, C17:0, C18:2, and trans-C18:1 accounted for 2.2, 5.7, 1.2, 1.5, 2.1, 3.0%, respectively of the total lipid content. The presence of the odd-number carbon chain (C17:0) might be indicative of ruminant fats [2, 19, 20]. However, in this case, no long fatty acids or alkanes (neither odd-numbered linear hydrocarbons) were revealed, unless aging and/or artificial degradation of beeswax by temperature may have been occurred [22].

Discussion

The accurate analysis of Roman’s wall painting components might be conditioned by the use of an efficient extracting method. Therefore, to improve the extraction process a mechanical pulverization of the painting powder was performed. In fact, the solid paint powder matrix might be compared to particles formed by an impermeable core covered by a porous organic layer. Efficient quantitative extraction must overcome interactions between analytes and matrix [23] thus, the fine reduction of particle size might assist the subsequent solubilization process [24]. Even though this procedure is well known, we addressed our work to assess if it could lead to a better extraction yield with respect to the procedure adopted in our previous works. The pulverization method was applied on five sporadic Pompeian wall painting specimens from Pompeii’s House of Golden Bracelet, Insula Occidentalis. The paint powder withdrawn from these samples was quantitated using a method based on FT-IR and was used to measure more accurately the weight of binders, pigments, and decaying compounds present in the painting powder. In fact, by summing the amount of total amino acids and lipids (in mg/kg) and convert it to percent unit, we obtained 0.88% of organic matter for S1, 0.37% for S2, 0.31% for S3, 0.24% for S4 and 0.73% for S5 (Table 2). These values represented the total amount of organic binder analyzed. Subtracting these values from the corresponding true paint percentage, we obtained the percentage values of pigments plus other organic compounds plus decaying compounds i.e.: 37.32% for S1, 39.33% for S2, 40.69% for S3, 41.56% for S4 and 43.27% for S5. Regarding the decaying compounds, because the formation of calcium oxalates (whewellite and weddellite) result from the bio-deterioration and/or deterioration of binders in ancient paintings [13, 25, 26], we tried to weigh up their presence by measuring the FT-IR peak area/μg of sample at 780 cm−1 (Table 2). Interestingly, the ratio between organic material percentage and the corresponding oxalate area/μg resulted higher in sample S1 and S5 (1.69 and 1.28, respectively) compared to samples S2, S3, and S4 (0.56, 0.45, and 0.54, respectively), thus suggesting that samples S1 and S5 were probably less bio-deteriorated/deteriorated compared to samples S2, S3, and S4. This observation is somehow in agreement with the higher content of ornithine found in samples S2, S3, and S4 compared to samples S1 and S5. It must be pointed out that these samples were collected from the same archaeological site of the specimens utilized in our previous studies: Villa Imperiale [6] and the house of Marcus Fabius Rufus [7]. All these fragments were stored in a preserved area of the site in order to avoid further environmental contamination. Moreover, because most specimens had same dating (from the first-century B.D. to first century A.D.), it could be assumed that they have more or less approximate levels of degradation/preservation as suggested by FT-IR calcium oxalate assessment. Furthermore, most of these specimens were also comparable for the type of color (pigments) used by artists such as red, green, brown and yellow [27].

The analytical procedure adopted allowed to obtain a recovery of lipids and amino acids of about one order and two orders of magnitude higher, respectively compared to our previous works. The differences can be most likely ascribed not only to quantitation method used to correct the amount of paint powder but also to more efficient extraction of the components after mechanical pulverization of paint powders. As found in our previous works [6, 7], also here the results showed in all samples the absence of proteinaceous material, even though the analysis was performed by ESI-Q-q-TOF, a high sensitive technique that allowed instead to highlight the presence of protein in a specimen form Liternum archaeological site [21]. Also the presence of free amino acids such as Ala, Ser, Pro, Asp, and Glu, at a concentration (2–3%) proportional to that present in different cereals and/or fruits, was observed [28, 29]. Moreover, additional lipids were detected such as C12:0, C14:0, C16:1, C17:0, and C18:0, thus confirming the improvement of the extraction procedure. The lipid profile (Table 4) suggested that oils of different origins were likely added to painting mixtures in agreement to Duran et al. [30] where the identification of non-polar organic material derived from oils or waxes in Pompeian’s paintings was reported. Our findings, together to those reported in our former analyses, confirm the hypothesis that Pompeian’s artists generally used a tempera or “a secco” technique made of colored pigments mixed to animal and/or vegetable organic binders to prepare the painting mixtures. Of course, the quality and the quantity of the results obtained might be influenced by the paint deterioration due to aging and environmental degradation [2].

Conclusions

In conclusion, the combination of the two pre-analytical procedures here described, the pulverization of the paint powder and the correction of the paint weight, lead to the more efficient recovery of organic materials. This aspect plays an important role for the qualitative and quantitative identification, by using different analytical methods, of the nature of polar and non-polar organic binders, and of pigments present in wall painting samples [6]. The use of this approach in future investigations on possibly more preserved archaeological samples will allow new perspectives in art and archaeological fields and for studying human habits [31].

Abbreviations

- FID:

-

flame-ionization detector

- FT-IR:

-

Fourier transform infrared spectroscopy

- GC:

-

gas chromatography

- HPLC:

-

high-pressure liquid chromatography

- MS:

-

mass spectrometry

- OPA-3-MPA:

-

o-phthaladehyde 3-mercaptopropionic acid

- SDS-PAGE:

-

sodium dodecyl sulphate-polyacrylamide gel electrophoresis

References

Ciardiello R. La casa del bracciale d’oro. In: Aoyagi M, Pappalardo U, editors. Pompei Insula Occidentalis. Valtren Editore; 2006. p. 71–560.

Colombini MO, Modugno F. Organic materials in art and archaeology. In: Colombini MP, Modugno F, editors. Organic mass spectrometry in art and archaeology. New York: Wiley; 2009. p. 3–36.

Evershed RP. Organic residue analysis in archaeology: the archaeological biomarker revolution. Archaeometry. 2008;50:895–924.

Domenéch-Carbò MT. Novel analytical methods for characterization of binding media and protective coatings in artworks. Anal Chim Acta. 2008;621:109–39.

Cuní J. What do we know of Roman wall painting technique? Potential confounding factors in ancient paint media analysis. Herit Sci. 2016;4:44.

Corso G, Gelzo M, Sanges C, Chambery A, Di Maro A, Severino V, Dello Russo A, Piccioli C, Arcari P. Polar and non-polar organic binder characterization in Pompeian wall paintings: comparison to a simulated painting mimicking an “a secco” technique. Anal Bioanal Chem. 2012;402:3011–6.

Gelzo M, Grimaldi M, Vergara A, Severino V, Chambery A, Dello Russo A, Piccioli C, Corso G, Arcari P. Comparison of binder compositions in Pompeian wall painting styles from Insula Occidentalis. Chem Cent J. 2014;8:65.

Lindon JC, Nicholson JK, Holmes E, Keun HC, Craig A, Pearce JT, Bruce SJ, Hardy N, Sansone SA, Antti H, Jonsson P, Daykin C, Navarange M, Beger RD, Verheij ER, Amberg A, Baunsgaard D, Cantor GH, Lehman-McKeeman L, Earll M, Wold S, Johansson E, Haselden JN, Kramer K, Thomas C, Lindberg J, Schuppe-Koistinen I, Wilson ID, Reily MD, Robertson DG, Senn H, Krotzky A, Kochhar S, Powell J, van der Ouderaa F, Plumb R, Schaefer H, Spraul M. Standard metabolic reporting structures working group. Nat Biotechnol. 2005;23:833–8.

Socrates G. Infrared and Raman characteristic group frequencies: table and charts. Oxford: Wiley; 2001.

Pecce R, Scolamiero E, Ingenito L, Parenti G, Ruoppolo M. Optimization of an HPLC method for phenylalanine and tyrosine quantization in dried blood spot. Clin Biochem. 2013;46:1892–5.

Chambery A, Di Maro A, Sanges C, Severino V, Tarantino M, Lamberti A, Parente A, Arcari P. Improved procedure for protein binder analysis in mural painting by LC-ESI/Q-q-TOF mass spectrometry: detection of different milk species by casein proteotypic peptides. Anal Bioanal Chem. 2009;395:2281–91.

Petrov I, Soptrajanov B. Infrared spectrum of whewellite. Spectrochim Acta. 1975;31A:309–16.

Bralia A, Matteini M, Moles A, Sabatini G. Ossalati di calcio sulla Fonte Gaia di Siena. In: Proceedings of the 1st international symposium the Oxalate Films. Origin and significance in the conservation of works of art. Centro Gino Bozza, Milan 1989, pp. 289-292.

Mills JS, White R. The organic chemistry of museum objects. Oxford: Butterworth Heinemann; 1994.

Weber AL, Miller SL. Reasons for the occurrence of the twenty coded protein amino acids. J Mol Evol. 1981;17:273–84.

Corso G, Esposito M, Gallo M, Dello Russo A, Malorni A. Transformation of arginine into ornithine during the preparation of its tert-butyldimethylsilyl derivative for analysis by gas chromatography/mass spectrometry. Biol Mass Spectrom. 1993;22:698–702.

Mills JS. The gas chromatographic examination of paint media Part I: Fatty acid composition and identification of dried oil films. Stud Conserv. 1966;11:92–107.

Charters S, Evershed RP, Blinkhorn PW, Denham V. Evidence for the mixing of fats and waxes in archaeological ceramics. Archaeometry. 1995;37:113–27.

Buckley SA, Clark KA, Evershed RP. Complex organic chemical balms of pharaonic animal mummies. Nature. 2004;431:294–9.

Evershed RP, Dudd SN, Copley MS, Berstan R, Stott AW, Mottram H, Buckley SA, Crossman Z. Chemistry of archaeological animal fats. Acc Chem Res. 2002;35:660–8.

Gelzo M, Chambery A, Severino V, Di Maro A, Schiano-Lomoriello F, D’Apolito O, Dello Russo A, Gargiulo P, Piccioli C, Arcari P. Characterization of pigments and ligands in a wall painting fragment from Liternum archaeological park (Italy). J Sep Sci. 2012;35:2986–93.

Regert M, Colinart S, Degrand L, Decavallas O. Chemical alterations and use of beeswax through time: accelerated aging tests and analysis of archaeological samples from various environmental contexts. Archaeometry. 2001;43:549–69.

Pawliszyn J. Kinetic Model of Supercritical Fluid Extraction. J Chromatogr Sci. 1993;31:31–7.

Favretto D, Vogliardi S, Stocchero G, Nalesso A, Tucci M, Ferrara SD. High-performance liquid chromatography high-resolution mass spectrometry and micropulverized extraction for the quantification of amphetamines, cocaine, opioids, benzodiazepines, antidepressants and hallucinogens in 2.5 mg hair samples. J Chromatogr A. 2011;1218:6583–95.

Salvadori B, Errico M, Mauro M, Melnik E, Dei L. Evaluation of gypsum and calcium oxalates in deteriorated mural paintings by quantitative FTIR spectroscopy. Spectrosc Lett. 2003;36:501–13.

Cariati F, Rampazzi L, Toniolo L, Pozzi A. Calcium oxalate films on stone surfaces: experimental assessment of the chemical formation. Stud Conserv. 2000;45:180–8.

Ergenc D, La Russa MF, Ruffolo SA, Fort R, Sanchez Montes AL. Characterization of the wall paintings in La Casa de los Grifos of Roman city Complutum. Eur Phys J Plus. 2018;133:355.

Mustafa A, Aman P, Andersson R, Kamal-Eldin A. Analysis of free amino acids in cereal products. Food Chem. 2007;105:317–24.

Ito H, Ueno H, Kikuzaki H. Free amino acid compositions for fruits. J Nutr Diet Pract. 2017;1:1–5.

Duran A, Jimenez De Haro MC, Perez-Rodriguez JL, Franquelo ML, Herrera LK, Justo A. Determination of pigments and binders in pompeian wall paintings using synchrotron radiation-high-resolution X-ray powder diffraction and conventional spectroscopy–chromatography. Archaeometry. 2010;52:286–307.

Kuckova S, Crhova M, Vankova L, Hnizda A, Hynek R, Kodicek M. Towards proteomic analysis of milk proteins in historical building materials. Int J Mass Spectrom. 2009;284:42–6.

Authors’ contributions

MG significant contributions to the experiment design, acquisition of data and sample analyses. RP was involved in amino acid analyses. CP and OA were involved in samples collection. ADR critically read the manuscript. GC and PA made substantial contributions to interpretation of data, drafting, and revision of the manuscript. All authors read and approved the final manuscript.

Acknowledgements

We wish to thank Prof. M. Osanna, Soprintendenza Speciale per i Beni Archeologici di Napoli e Pompei, for the access to Pompeii’s archaeological area.

Competing interests

The authors declare that they have no competing interests.

Availability of data and materials

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Funding

This work was supported by funds from Programmi di Ricerca Scientifica di Rilevante Interesse Nazionale (2012CK5RPF_004), PON Ricerca e Competitività 2007–2013 (PON01_02782) and POR Campania FSE 2007–2013, Project CRÈME.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Gelzo, M., Corso, G., Pecce, R. et al. An enhanced procedure for the analysis of organic binders in Pompeian’s wall paintings from Insula Occidentalis. Herit Sci 7, 12 (2019). https://doi.org/10.1186/s40494-019-0254-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-019-0254-1