Abstract

The aim of this study was to develop new, sustainable treatments for the consolidation and conservation of canvas of modern and contemporary art. Because of the diversity of painting types, two product groups which have polar and nonpolar character were developed. The treatment should be applicable to the back side of the canvas. The deacidification agents are sub-µm-particles of calcium carbonate or magnesium oxide which are dispersed in water or heptane. The polar components are hydroxyethyl methyl cellulose and nanocrystalline cellulose which are biopolymers derived from renewable raw materials. The nonpolar products were obtained by the silylation of the raw materials and allow the solubility in nonpolar solvents as heptane. Each product was applied to highly degraded, acidic model cotton canvas as well as canvas from real paintings. The application of these products showed a good increase of breaking force at a low increase of the mass of the canvas and also had only slight optical changes of the canvas. The deacidification of canvasses is a good preventive measure and can protect canvasses from future damage by acidity. The deacidification agents showed an increase of pH from acidic to alkaline after the treatment and a deposition of an alkaline reserve.

Similar content being viewed by others

Introduction

So far, the restoration of canvas paintings has often concentrated on the face of the painting. Problems included yellowed varnishes, flaking of the painting layer, craquelure and others. But the canvasses of many paintings have also become very weak by oxidative and acid-catalyzed degradation reactions in the past centuries. The degradation processes cause disruptions and cracks which endanger the paintwork of the entire picture.

Due to the manifold used substances, there are several main difficulties in developing an appropriate treatment. The whole system of canvas and paintwork is extremely sensitive against any type of solvents. Polar solvents like water make the fibers swell and can dissolve the colored degradation products of the canvas. Nonpolar solvents affect the binders of oil paints and varnishes. The challenge was to develop a system for deacidification- and stabilization which has none or as few as possible negative side effects on the object. This can be achieved with a short contact time of the solvent and the canvas, either by a very low solvent concentration or with a high volatile solvent.

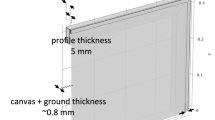

Furthermore, the treatment shall achieve a high stabilization of the canvas. To prevent any tension in the canvas, the elasticity and reaction to humidity changes of the stabilization film need to be similar to the ones from canvas or even less. The stabilization film also needs to have the lowest possible weight, to avoid any further mechanical stress or damage caused by extra added weight.

This work focused on canvasses of easel paintings which are made of cotton, jute or linen. All these painting supports have in common that they consist of cellulosic material. Out of the manifold layers of the canvas, there may be migration of acids from varnishes or binding materials through the canvas. In addition, acidity may come from the degradation of the cellulose itself or the polluted environment. The main reasons for the degradation of cellulosic material are acid catalyzed hydrolysis and degradation by sulphur dioxide and nitric oxides from air pollution. If no neutralization of the acids takes place, the fibers of the canvas become more and more brittle. As a result, there will be serious damages in the fabrics. Another aspect is the oxidative degradation which occurs if the painting layer contains heavy metal ions as iron or copper [1].

Cellulosic materials can also be degraded thermally, by photolysis and by microorganisms or fungi [1]. However, these subjects were not part of the study and are excluded.

The main difficulty, the acid catalyzed degradation mechanism, can be stopped if the acids are neutralized. Methods for the deacidification of canvas paintings were reported which are with calcium hydroxide in water, magnesium bicarbonate in water and magnesium methoxy methyl carbonate in methanol and trifluorochloroethane [2,3,4]. All three deacidification methods showed a decreased degradation of the deacidified canvas in relation to the untreated canvas when the samples underwent an accelerated ageing. However, these methods also have disadvantages. Depending on the type and the nature of the canvas painting there might be a high sensitivity against humidity. In that case it is not desirable to apply water-based deacidification agents. Solvent-based systems may be an alternative. The magnesium methoxy methyl carbonate is solved in methanol and trifluorochloroethane which is a very polar solvent. Polar solvents may cause other problems like fading of colors and pigments. Another aspect about trifluorochloroethane is that it belongs to the group of chlorofluorocarbons which are forbidden because of the environmental impact of these solvents. There is an urgent need to develop new products which avoid the impact of solvents on the canvas paintings.

The use of nonpolar solvents like pentane, heptane or comparable nonpolar solvents is desirable to avoid the interaction between polar components of the canvas and the nonpolar solvent. However, there is still a risk of interaction of the nonpolar solvent with nonpolar substances out of the canvas painting layers. Summarizing, it would be the best way to develop several products and choose an appropriate treatment depending on the type and nature of the painting.

The deacidification process will not improve the mechanical properties of an already highly degraded canvas but it will help to prevent further damages. An additional consolidation is needed for already degraded canvasses.

The aim of this study is to use nanocellulose for the consolidation. Nanocellulose itself is a term used for cellulosic nanostructures. There are three groups of nanocelluloses which are nanocrystalline cellulose, microfibrillated cellulose and bacterial nanocellulose. Nanocrystalline and microfibrillated cellulose are produced top-down by chemical and mechanical disintegration from plants whereas bacterial nanocellulose is obtained bottom-up by biosynthesis [5,6,7]. For the use of nanocellulose in the area of painting restoration a few works were reported recently [8,9,10,11]. Nechyporchuk et al. [11] showed that the stabilization effect of different nanocellulose types on canvas is higher than the effect of an often used wax-resin formulation (BEVA 371). Nanocellulose was also used in combination with nanosilica particles by Kolman et al. [10] and showed a high potential in stabilization in different length scales of the canvas. But there were also some difficulties when using nanocellulose on canvas which was shown by Bridarolli et al. [9]. There was a poor adhesion between nanocellulose and the fiber of the canvas when nanocellulose was used alone.

In this study the idea for the stabilization was to create a nanocomposite. Nanocomposites are defined as materials consisting of a polymer and a nanomaterial which can be of a different kind (e.g. particles, fibers). The polymer matrix of the nanocomposite should enhance the connection of canvas fiber and nanocellulose.

A transfer of the consolidation agents to a solvent based system is needed to avoid the already named impact of polar solvents on the canvas. Nanocellulose has a high surface area and a large amount of hydroxyl groups is available on its surface. Because of its high polarity it cannot be dispersed in nonpolar solvents. Different surface modifications of nanocellulose were described which are esterification with acetic anhydrides or carboxylic acids, silylation, grafting of polymers onto the surface of the nanocellulose and other modifications [5]. The silylation is a reaction which introduces hydrophobic groups into the nanocellulose molecule and meets the requirements.

Experimental

Deacidification agents

CaCO3 in water and MgO in heptane dispersions were developed and produced by ZFB—Zentrum für Bucherhaltung GmbH, Germany. The particle size of the dispersions is in the sub-µm region which means it is under 1 µm.

Consolidation agents

Hydroxyethyl methyl cellulose (Tylose® MH), hydroxyethyl cellulose (Tylose® H) and methylcellulose (Metolose®) were purchased from Shin-Etsu Chemical Co., Ltd. Polyvinyl alcohol (Selvol™) was purchased from Sekisui Chemical Co., Ltd.

Cellulose fibers (JELUCEL®) were purchased from JELU-WERK Josef Ehrler GmbH & Co. KG. Cellulose powder (Arbocel®) was purchased from JRS Rettenmaier & Söhne GmbH + Co KG. Nanocrystalline cellulose (CelluForce NCC™) was purchased from CelluForce inc.

Derivatization agents

Ethylene diamine (≥ 99.5%), hexamethyldisilazane (≥ 99.5%), methanol (≥ 99%), toluene (≥ 99.5%), imidazole (≥ 99%) and tetrahydrofuran (≥ 99.5%) were purchased from Carl Roth GmbH + Co. KG. Trimethylsilyl chloride (≥ 99%) was purchased from Sigma-Aldrich Chemie GmbH.

Canvas samples for treatment

Linen and jute canvas were purchased at Lienzos Levante (Valencia, Spain). Cotton canvas was purchased from Barna Art (Barcelona, Spain). The grammage was 200 g/m2 for the linen, 300 g/m2 for the jute and 417 g/m2 for the cotton canvas. Linen, cotton and jute canvas were pretreated and an accelerated ageing was performed. The pretreatment process included cutting, boiling, acidification with alum, stretching, animal glue sizing, cutting and labeling. The pretreated linen, cotton and jute were oven aged at 90 °C and 65% RH in a climate chamber (climate chamber, CC) for 18 days. Another ageing mechanism was developed by Nechyporchuk et al. [12]. The method proposes the oxidation of the canvas by hydrogen peroxide and sulfuric acid (acid aged, AA). Untreated cotton canvas as bought from the shop was used for this method. Mechanical testing was performed to all the samples.

Treatment was also done on original paintings which were “The musician” (oil painting on linen canvas), “Angels” (acrylic paint on linen canvas), “Portrait of a woman” (oil painting on linen canvas), and “African women” (acrylic paint on cotton canvas). All paintings were contemporary art.

Preparation of biopolymer and (nano)composite films

Hydroxyethyl methyl cellulose (HEMC), methyl cellulose (MC), hydroxyethyl cellulose (HEC) and polyvinyl alcohol (PVA) solutions were prepared by diluting the substances in water. For each material films with a dry grammage of 50 g/m2 were prepared in silicon molds by casting-evaporation technique. All samples were dried at room temperature for several days.

For the testing of different fibers and nanocrystalline cellulose as (nano)composites, the fibers were mixed into the matrix with a proportion of 10% of the matrix. For the nanocrystalline cellulose the percolation theory was applied [6]. The nanocrystalline cellulose can be described as rod shaped particles with a given length L and diameter d. The ratio of length to diameter gives the so-called aspect ratio L/d. For a given aspect ratio of the nanocrystalline cellulose it is possible to predict the concentration which is needed to form a rigid network of the nanocrystals in a polymer phase. The so-called percolation threshold is given by the formula:

VRc is the volume fraction of cellulose nanoparticles needed to achieve geometrical percolation. The size of the nanocrystalline cellulose is given with a diameter of 5–10 nm and a length of 80–150 nm. The volume fraction was calculated with an average value of 4.5%. Nanocrystalline cellulose was mixed into the matrix with a proportion of 4.5% of the matrix.

Films with a dry grammage of 50 and 100 g/m2 were prepared from all mixtures.

Mechanical testing

Mechanical testing was carried out on a Zwick Tensile Testing Machine Type BDO-FB0.5Ts with force sensor KAF-Z500. Measurements of canvas samples were performed at an extension rate of 100 mm/min. Samples were fixed in the machine with a jaw distance of 2 cm. The upper jaw slides apart till the sample breaks. The breaking force and the elongation of each sample were recorded.

For the measurement of the biopolymer and nanocomposite films, the method was adapted to a jaw distance of 1 cm and an extension rate of 3 mm/min.

Transfer to solvent based system

The solubility of a substance in a desired solvent depends on the chemical characteristics of both. Hydroxyethyl methyl cellulose is soluble in water but in non-polar organic solvents it is not because there are a lot of very polar hydroxide groups in the chemical structure.

To change the solubility of the hydroxyethyl methyl cellulose, it is necessary to replace the hydrophilic hydroxide groups by hydrophobic side groups. A common reaction for this problem is the silylation. The silylation is a chemical derivatization where a substituted silyl group (R3Si) is introduced into the molecule. For the silylation of the cellulose ethers used in this project the substituted group is a trimethylsilyl group (TMS). So, if hydroxyethyl methyl cellulose is persilylated by a silylating agent, the solubility in non-polar solvents can be achieved. In the persilylation process hydrogen of all hydroxide groups were replaced by trimethylsilyl groups according to formula (2).

In a common procedure hydroxyethyl methyl cellulose was pretreated with ethylene diamine and then persilylated with hexamethyldisilazane as silylating agent and solvent with catalytic amounts of trimethylsilyl chloride. To remove unreacted educts and byproducts the silylated hydroxyethyl methyl cellulose was washed by methanol and dried under vacuum.

For the silylation of nanocrystalline cellulose, the material was pretreated in toluene and then surface groups were silylated with trimethylsilyl chloride as silylating agent and with catalytic amounts of imidazole. To remove unreacted educts and byproducts, the silylated nanocrystalline cellulose was washed by methanol/tetrahydrofuran (20/80 v/v %) and dried under vacuum.

For the evaluation of the degree of substitution of Si–(CH3)3-groups in the HEMC ATR-FTIR analysis was performed. The obtained product was oven dried to remove water. The sample was then directly placed onto the ATR-crystal and measured. The instrument used was a FTIR spectrometer Tensor27 by Bruker Optics GmbH.

Alkaline reserve and pH measurements

Canvas supports consists of cellulose, as do paper objects. Measurements of alkaline reserve and pH were performed according to standards for paper because of the similarity. The aim of the deacidification is to neutralize acids in the material and to deposit an alkaline reserve to protect the canvas from future damages by acids. The highly degraded cotton canvas (AA) was deacidified with nano dispersions of 10 g/l MgO in heptane and 30 g/l CaCO3 in water. The nano dispersions were applied to the canvas with a brush in one layer.

The alkaline reserve was measured according to ISO 10716. A sample of 1 g is needed for the determination. The sample is soaked in 100 ml distilled water and cooked for 5 min. After cooling of the mixture, a defined amount of hydrochloric acid is added and boiled again. The cooled suspension is titrated with sodium hydroxide with methyl red indicator to the first lemon-yellow color. The amount of alkali in moles per kg of the cellulosic material is calculated.

The surface pH was measured according to TAPPI T 529 om-04. A drop of distilled water is placed on the cellulosic material. The measurement is carried out with a flat combination electrode which is immersed into the drop of water and the pH is measured to the nearest 0.1 pH unit.

The measurement of cold extract pH was carried out according to ISO 6588-1. A sample of 2 g cellulosic material per 100 ml distilled water is needed and soaked in the water for 1 h. The pH of the decanted extract is measured to the nearest 0,1 pH unit.

Application of nanocomposites on model cotton canvas

For the evaluation of the mechanical reinforcement, the nanocomposite mixtures have been applied to the highly degraded model cotton canvas (AA). There were two mass uptakes tested which are 5 and 10% in relation to the grammage of the untreated canvas. Because of the limited material, two small pieces of 2 × 8 cm were treated for each polar and nonpolar substance and mass uptake. The samples were characterized by stress–strain measurements after the treatment and again after accelerated ageing. For each treatment 4 samples could be measured.

Color measurements

The color of canvas samples before and after the treatments as well as after the accelerated ageing was measured with the spectrophotometer CM 2600d (Konica Minolta). The spectrophotometer measures the coordinates of L*a* and b* of the samples according to the CIE L *a*b* color space using three xenon flash lamps. The CIE L*a*b* color space describes colors that are visible to the human eye by three coordinates. L* describes the lightness of the color from 0—black to 100—white, a* describes the position between red and green and b* describes the position between yellow and blue. To evaluate a color difference of two colors, the distance between these colors can be calculated according to ISO 12647:

Accelerated ageing experiments

Canvas samples that were treated with nanocomposites have been aged accelerated in a climate chamber Heraeus Voetsch HC 0020 for 2 weeks at a temperature of 80 °C and a relative humidity of 65%.

Adhesion tests

Arbocel®BC 1000 was bought from Rettenmaier and Sohne SARL (France). It is a cellulose powder made of fibres of, in average, 700 µm and 20 µm in length and diameter, respectively. The powder is insoluble in water. A few droplets of the nanocomposite were deposited on a small amount of cellulose powder which had been previously pressed onto a glass slide to obtain a flat surface. The amount of solution deposited and cellulose powder used was kept similar for each treatment tested.

Results and discussion

Mechanical testing of untreated canvas

Mechanical testing of untreated canvasses was necessary to evaluate the variations of breaking force of the material. The samples that were aged in the climate chamber (CC) have values of 44–74 N. Each type of canvas showed a non-uniform value for the breaking force which can be seen in the standard deviation of 8–14 N. The highly degraded cotton canvas which was aged by acids (AA) showed a more uniform breaking force of 46 N ± 3 N (Fig. 1). The cotton AA sample was used for all tests because of the lowest standard deviation. Consolidation treatments which lead to a stabilization over 7% can be proven as significant stabilization effects.

Biopolymers for composites

The biopolymer films of methyl cellulose (MC), hydroxyethyl cellulose (HEC), hydroxyethyl methyl cellulose (HEMC) and polyvinyl alcohol (PVA) were characterized by mechanical testing (Fig. 2).

The comparison of the biopolymers show that HEC has the lowest tensile strength, is followed by PVA and HEMC and MC have the highest tensile strength. For further experiments HEMC was used. Among the tensile strength the HEMC in comparison to MC showed more advantages. Because of its hydroxyethyl groups it can be diluted more easily in water and shows a better workability in general.

Composite systems

The biopolymer HEMC itself shows an average basis tensile strength which may not be enough to stabilize canvas materials and for this reason it should be enhanced by the addition of fiber material. For fiber materials, first cellulose fibers of a length up to 1000 µm, microcrystalline cellulose and nanocrystalline cellulose were used as fillers for the matrix.

Tensile strength was measured and the increase of tensile strength due to the fibers and nanomaterial was calculated. For the cellulose fibers from 5 up to 1000 µm there was an increase of tensile strength of the compound with growing fiber length. The reason is that longer fibers can transform the applied strength more onto the matrix and surrounding fibers. The nanocrystalline cellulose showed a comparable increase of tensile strength to the cellulose fibers with a length of about 1000 µm (Fig. 3). The nanocrystalline cellulose with a very short fiber length is as good as long fibers because of its higher surface area which leads to higher interaction of the particles and therefore a higher tensile strength.

Nanocrystalline cellulose was chosen as filler for the matrix system. The composite can be classified as nanocomposite system. The main advantage beside its consolidation effect is the invisibility of the nanocrystals in the biopolymer matrix unlike the other tested cellulose fibers.

Evaluation of silylated products

The FTIR-ATR spectrum of HEMC (Fig. 4) shows Si–CH3 stretching vibration at 1250 cm−1 and Si–CH3 rocking vibration at 837 and 748 cm−1. C–O–Si bond is given by asymmetrical stretching vibration at 1041 cm−1. There is also C–H stretching vibration at 2953 cm−1 and C–O–C asymmetrical stretching vibration at 1121 cm−1. In the spectrum there was no band for O–H bonding which would be found at 3200–3600 cm−1 which indicates that there were no –OH-groups in the molecule.

Deacidification of model cotton canvas

The untreated highly degraded cotton canvas was acidic and after each treatment with polar or nonpolar deacidification agents, an alkaline reserve was deposited and the pH was alkaline. The values for surface pH and pH as cold extract increased from 4.3–5.8 to 7.9–9.1. The alkaline reserve increased by 0.13–0.16 mol/kg as measured according to ISO 10716 (Table 1).

Consolidation of model cotton canvas

The aim of the canvas consolidation is to achieve a high stabilization at a low mass uptake. The untreated highly degraded cotton canvas had a breaking force of 46 ± 3 N. All treatments with polar and nonpolar nanocomposites led to a breaking force higher than this value and can be proven as significant effects. The breaking force after treatment with nanocomposites is around 55–69 N (Table 2). All samples were treated by brushing the mixtures onto them. The brushing technique on the small samples may lead to a non-uniform layer of the consolidant. This may explain the dispersion of the measurements. The accelerated ageing of the untreated but already highly degraded cotton canvas led to a decrease of breaking force to 31 N. The treated and accelerated aged samples still had a breaking force of 50–55 N.

Optical changes of treated model cotton canvas

To evaluate color changes after the treatment as well as after the accelerated ageing color measurements were performed. The color difference ∆E was calculated. A value of ΔE of 1 – 2 means that there is a slight color difference which can already be observed by the eye. If ΔE is higher than 5 the colors are different. Each treated sample before and after accelerated ageing was measured three times. The ΔE was calculated in relation to the untreated highly degraded model cotton canvas (Table 3). The ∆E values after the treatment with nanocomposites were in the range of 1–2 which means that the color of the canvas changed slightly.

After the accelerated ageing the untreated canvas had ∆E of 20 in relation to the untreated, new canvas and the treated samples had ∆E of 13–14 (Table 4). These values indicate a significant color change. Especially the b* of the L*a*b* color system showed a high difference in positive direction which can be interpreted as a shift to a more yellow color. Also, the values for L* were lower which indicates a darkening. However, the untreated and aged sample had the highest color change which can be associated with the oxidation by the ageing experiment. The color changes were lower when the samples were treated with the nanocomposites.

Application on original paintings

The developed nanocomposites were tested by a painting conservator. The assessment of the mixtures was done according to five criteria (Table 5). The treatment should be chemically compatible to the substrate, should be applicable easily and homogenously to the canvas, should not modify the canvas and painting appearance, should not penetrate through the paint layer and should provide enough reinforcement to the canvas.

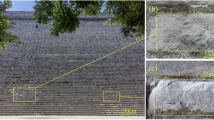

The polar and nonpolar products were applied to several canvas types with a brush (Fig. 5). The canvas was then dried and optical and surface changes were documented (Fig. 6).

Linen lining canvas with high density weaving before (a) and after (b) treatment with polar nanocomposite and before (c) and after (d) treatment with nonpolar nanocomposite; Linen lining canvas with low density weaving before (e) and after (f) treatment with polar nanocomposite and before (g) and after (h) treatment with nonpolar nanocomposite

Overall, the water-based products are suitable in terms of penetration, surface deposition, canvas visual appearance and consolidation (feeling to the touch). They have acceptable viscosity but this one can be easily modified if necessary. Slight darkening of some of the canvasses could, however, be observed in some cases where a large amount of consolidant was applied. This should be kept in mind when using the product. The color changes were not measured with the L*a*b*-method because the evaluation of the products took place at a workshop and the equipment could not be brought there.

The heptane-based products present the same advantages. However, a disadvantage of these treatments is the whitening observed when these treatments are used on dark canvasses. The products have a fast-drying time. The advantage is in the reduction of the duration of the application but has, as well, the disadvantage to give less room for control during the application of the product.

Conclusions

The aim of this work was to develop treatments for the deacidification and consolidation of canvas. Because of the different nature of canvas paintings (canvas painting support, paints) two product groups which have polar and nonpolar character were developed. The polar deacidification agent consists of CaCO3 particles in water. The polar consolidation components are hydroxyethyl methyl cellulose and nanocrystalline cellulose which are in water. For the nonpolar consolidation agents, a derivatization by persilylation of the hydroxyethyl methyl cellulose and a surface silylation of the nanocrystalline cellulose was performed. The deacidification agent is MgO particles in heptane. The main advantage of the silylation reaction is that the consolidation agents become soluble in the nonpolar solvent heptane and therefore the risks of water-based products can be avoided.

The application of both polar and nonpolar deacidification agents on a highly degraded, acidic model cotton canvas by brushing led to an increase of pH and an alkaline reserve was deposited into the material. The application of the polar and nonpolar consolidation agents increased the breaking force of the canvas by 17–38% depending for the polar system and 36–42% for the nonpolar system. The stabilization effect is higher for the nonpolar system. It can be summarized that the stabilization effect after silylation reaction is as good as for the polar nanocomposites and the interaction between the materials and the canvas is comparable.

The optical changes of the white model cotton canvas were minimal and showed a slightly yellowing of the material. The application on naturally aged canvasses showed a slightly darkening for the polar treatments and a slightly whitening for the nonpolar treatments. The darkening by the polar treatments may come from the dilution of polar contaminants which are deposited in the canvas over time because water tends to swell the cellulose fibers. The risk of side effects like dilution of contaminants is minimized for the nonpolar system because it doesn’t swell the fibers.

An accelerated ageing of the deacidified and consolidated samples was performed. After the ageing experiments the breaking force of the treated canvas samples was still higher than the untreated, not aged canvas. Especially the treatment with the nonpolar nanocomposite showed a high sustainability.

The developed products offer a good range of materials and can be used for deacidification as a preventive measure for the protection of canvasses from degradation by acids. For already degraded and acidic canvasses the deacidification and consolidation can be performed. The main advantage of the products is that they offer a good stabilization effect at a minimum weight increase if compared to the lining technique where a new canvas is put on the already damaged canvas.

Availability of data and materials

The datasets analysed during the current study are not publicly available but are available from the corresponding author on reasonable request.

Abbreviations

- AA:

-

Acid aged

- ATR:

-

Attenuated total reflection

- CC:

-

Climate chamber

- FTIR:

-

Fourier-transform infrared spectroscopy

- NCC:

-

Nanocrystalline cellulose

- HEC:

-

Hydroxyethyl cellulose

- HEMC:

-

Hydroxyethyl methyl cellulose

- MC:

-

Methyl cellulose

- PVA:

-

Polyvinyl alcohol

- PVC:

-

Polyvinyl chloride

- PE:

-

Polyethylene

- PMMA:

-

Poly(methyl methacrylate)

- PS:

-

Polystyrene

References

Stoner JH, Rushfield R. Conservation of Easel Paintings. Hoboken: Taylor and Francis; 2012.

Kerr N, Hersh SP, Tucker PA. Physical changes of alkaline-buffered cotton fabric. In: ICOM Committee for Conservation, 7th Triennial Meeting, Copenhagen. 1984. p. 9.25–9.29.

Hackney S, Townsend J, Wyplosz N. Studies on the deacidification of canvas supports with magnesium methyl methoxycarbonate (MMC). In: Pre-prints of Edinburgh Conference, ICOM Committee for Conservation. 1996:271–5.

Hackney S. Paintings on canvas: lining and alternatives. Tate papers. 2004.

Kargarzadeh H, Ahmad I, Thomas S, Dufresne A. Handbook of nanocellulose and cellulose nanocomposites: Volume 1. Weinheim: Wiley; 2017.

Dufresne A. Nanocellulose: from nature to high performance tailored materials. 1st ed. Berlin: Walter de Gruyter GmbH Co.KG; 2012.

Witten E, editor. Handbuch faserverbundkunststoffe/composites: Grundlagen, Verarbeitung, Anwendungen. 4th ed. Wiesbaden: Springer; 2014.

Bridarolli A, Nechyporchuk O, Odlyha M, Oriola M, Bordes R, Holmberg K, et al. Nanocellulose-based materials for the reinforcement of modern canvas-supported paintings. Stud Conserv. 2018;63:332–4. https://doi.org/10.1080/00393630.2018.1475884.

Bridarolli A, Odlyha M, Nechyporchuk O, Holmberg K, Ruiz-Recasens C, Bordes R, Bozec L. Evaluation of the adhesion and performance of natural consolidants for cotton canvas conservation. ACS Appl Mater Interfaces. 2018;10:33652–61. https://doi.org/10.1021/acsami.8b10727.

Kolman K, Nechyporchuk O, Persson M, Holmberg K, Bordes R. Combined nanocellulose/nanosilica approach for multiscale consolidation of painting canvases. ACS Appl. Nano Mater. 2018;1:2036–40. https://doi.org/10.1021/acsanm.8b00262.

Nechyporchuk O, Kolman K, Bridarolli A, Odlyha M, Bozec L, Oriola M, et al. On the potential of using nanocellulose for consolidation of painting canvases. Carbohydr Polym. 2018;194:161–9. https://doi.org/10.1016/j.carbpol.2018.04.020.

Nechyporchuk O, Kolman K, Oriola M, Persson M, Holmberg K, Bordes R. Accelerated ageing of cotton canvas as a model for further consolidation practices. J Cult Herit. 2017;28:183–7. https://doi.org/10.1016/j.culher.2017.05.010.

Acknowledgements

Not applicable.

Funding

This work was part of the project NANORESTART (NANOmaterials for the RESToration of works of ART) and was funded by European Union’s Horizon 2020 research and innovation program under Grant Agreement No. 646063.

Author information

Authors and Affiliations

Contributions

All authors contributed to the research. MA and NB developed the nanocomposite mixtures, performed all experiments and measurements, interpreted the data and wrote the manuscript. TR performed all silylation experiments for the derivatization of cellulosic materials. KS helped writing the manuscript. AC and AB performed experiments on real paintings, evaluated the developed products and helped writing the related part of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Böhme, N., Anders, M., Reichelt, T. et al. New treatments for canvas consolidation and conservation. Herit Sci 8, 16 (2020). https://doi.org/10.1186/s40494-020-0362-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-020-0362-y