Abstract

Gutta percha, natural rubber, and balata are latexes produced by tropical trees that since the mid-nineteenth century have been extensively used commercially and in the creation of artworks and daily use objects. All three latexes are stereoisomers of polyisoprene that differ in their molecular structure. In gutta percha and balata, the molecular functional group is in the trans- position; in natural rubber, it is in the cis- position. This difference in their molecular structure affects the physical properties of these materials and their aging, turning natural rubber tacky and gutta percha brittle. Commercially focused analysis of natural polyisoprenes has typically used chemically modified materials. The present study characterizes natural, chemically unadulterated latex harvested from trees, aiming to differentiate the cis- and trans-forms. The analysed materials comprised fresh latexes harvested in Malaysia and Indonesia, naturally aged botanical samples, some over 100 years old, and minimally processed 10-year-old commercial stock; a total of 50 samples were examined, out of which 23 are discussed in detail. The harvesting practices of latexes were recorded during fieldwork in Southeast Asia in 2015–2019, in Cipetir (Tjipetir), on Lingga Island in Indonesia, and in Malay rubber plantations. The harvesting methods are the first indicators as to the type of latex harvested based on the pattern of incisions and time of coagulation upon exposure to air. The interviews of tappers, especially of gutta percha and balata, serve as a record of a disappearing craft. Therefore, this fieldwork report contributing to a general knowledge of working methods with natural latexes is of particular value considering the scarcity of published records. The laboratory analytical study of trans- and cis- forms relied on nuclear magnetic resonance (NMR) spectroscopy, which is the most accurate method to unambiguously determine the stereo chemistry of each polyisoprene. The characteristic spectroscopic features of cis- and trans-positions were clearly shown in all samples, in fresh latex, in over 100-year-old material, and in early twentieth century artifacts. This result indicated that the aging of the polyisoprenes does not prevent the identification of their stereochemistry. This analytical work is the first thorough examination of gutta percha, natural rubber and balata in the context of cultural heritage to guide preservation strategies for objects made of these materials.

Similar content being viewed by others

Introduction

Gutta percha, natural rubber, and balata are natural latexes produced by plants growing in various tropical climates, from South America to Africa to Southeast Asia. Latexes produced by plants are colloidal mixtures of particles, water, and chemically complex liquids containing sugar, proteins, and resins, among other elements. All three latexes discussed here are natural polyisoprenes with the same empirical chemical formula, (C5H8)n. Although over 2000 plants are estimated to be laciferous [1], the most commercially viable latexes of gutta percha and natural rubber were harvested from tropical trees in Southeast Asia; balata was represented by 15 species in that region [2]; however, the most extensive harvest of balata was reported in tropical America. Currently, only natural rubber is still harvested, although that is not nearly as extensive as in the past century.

The latexes of gutta percha, balata, and natural rubber at the end of the nineteenth century changed the architecture of world commerce, communication, and politics. From 1851, gutta percha, sometimes with the addition of balata, [3,4,5,6,7,8] was used to insulate underwater communication cables, facilitating the first telegraphic communication between England, Europe, and the Americas [9]. The increase in the speed of information transmitted across the continents changed everything from commercial trade to global politics. Natural rubber was used in pneumatic tires in approximately 1890, transforming the automobile industry; natural rubber is today still a strategic material of immense economic importance. Balata was used as an additive to and sometimes a substitute for both gutta percha and natural rubber, and for many years, it was applied as a reinforcement of industrial conveyor belts [5, 7, 8]. Balata was also known as a coating for porous materials, including paper [3, 10]. Gutta percha and balata, in addition to their industrial importance, were used to create artworks, furniture elements, decorative components, and objects of daily use, such as trays and cups [4, 5, 10,11,12]. Gutta percha, an easily molded thermoplastic, was considered a miracle material that could easily be shaped into commemorative medallions, plaques, and decorative accessories, some of which were examined during this study.

The commercial importance of gutta percha and balata, once their properties were discovered around 1840–45, resulted in extensive exploitation of natural resources, cutting down trees from which the latexes were harvested. The greatest demand for latexes came in constructing transatlantic telegraphic cables, up until the early twentieth century, when synthetic polymers replaced natural products [13,14,15]. Today, the harvest of gutta percha and balata in Southeast Asia is nonexistent mainly because there is no demand for these natural materials, and the only known contemporary application of gutta percha is in dental obturation of root canals and prosthetic components [13, 16].

Natural rubber is still harvested on rubber plantations in Indonesia and Malaysia and remains an important commodity despite the increased use of its synthetic substitutes. Research of natural rubber is immense; therefore, only the most relevant findings are cited here.

The harvesting methods of each latex differ mainly because each latex reacts differently when exposed to air. Natural rubber flows freely while gutta percha does not produce a drop, solidifying on the incised bark; thus, a method of harvesting is the first indicator of what type of latex is being extracted. There is no reported observation of balat coagulation, although the existing scarce reports refer to harvesting ballata in a similar manner as gutta percha. This study reports on the harvesting practices recorded during the field work in Southeast Asia 2015–19, and interviews of tappers who recalled from years back this disappearing craft and thus may serve as the only contemporary record of once booming commerce; the detailed description of the harvesting practices follows in “Harvesting methods of gutta percha, natural rubber, and balata” section.

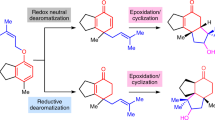

The historical and commercial importance of these natural polyisoprenes and their presence in museum collections prompted this extensive laboratory analysis, which focused on the molecular stereo geometry of polyisoprenes. The cis- or trans-form of each polyisoprene that defines each polyisoprene as natural rubber or gutta percha is responsible for the different chemical and physical properties of each material and the manifestation of different aging patterns. Only gutta percha performed well in cold, salty waters and therefore could be used as an insulating material for underwater telegraphic cables. Natural rubber, on the other hand, can be vulcanized and employed in automobile tires. If those treatments were reversed, both materials would have lost their advantageous features; natural rubber would deteriorate on the ocean floor, and gutta percha could not be vulcanized. A precise determination of cis- and trans- positions can be accomplished using nuclear magnetic resonance (NMR) spectroscopy. The geometry of the isomerism of cis- and trans-polyisoprene was proposed as early as 1940 [17]; however, it could not be analytically proven due to a lack of instrumentation. The investigations continued through the mid-twentieth century. Most of the reported analytical work, however, used chemically and physically manipulated natural latexes; solvents and heat were applied to purify gutta percha or balata from resins that are typically part of raw latexes, and physical stretching transformed the raw latexes into sheets. Each of these preparatory methods changed the properties of the natural polyisoprenes. One example would be the heating of natural rubber, which results in transparent, tough films (samples RRIM, Attachment Additional file Appendix I, 1: Table 2). Alterations of the natural latexes that affect their analysis have been stressed by other researchers [18, 19]. However, the cis- or trans-positions remain fundamentally unchanged. This is in disagreement with one of the most prolific researchers of polyisoprenes, Tanaka (1990) [20], who postulated that trans- can change into cis-. That position is not supported by other researchers who firmly state that those two forms are never found together in naturally harvested latexes or can transform one into the other. The authors of this paper also could not confirm Tanaka’s position. The statement by Tanaka about one form changing into another leads to erroneous conclusions and negates the significant differences between gutta percha and natural rubber. To add to the confusion of nomenclature, even the most recent research reports, such as one authored by Chen et al. [21], interchangeably refer to cis- and trans-microstructures as different forms of rubber, which only stressed the need for clarification. In another recent report by Wei et al. [22], the authors explicitly stated that “trans- 1,4 polyisoprene is the isomer of natural rubber, cis-1,4 polyisoprene”, which is incorrect.

The design of this analytical study aimed to (1) examine fresh latex from known botanical sources to identify the composition of pure latexes, (2) compare the results with aged specimens, and (3) identify chemical features in artifacts made of gutta percha, natural rubber, if possible, from balata. The study design guided the search for samples fitting these general criteria.

Fresh, pure latex samples unadulterated by chemical treatments, temperature, or physical manipulations were harvested during field work in 2015–2019 in Southeast Asia from trees historically known as sources of high-quality gutta percha, natural rubber, and balata, Palaquium gutta, Hevea brasiliensis, and Manilcara bidentata, respectively [5, 6, 10]. The archival botanical samples, some over 100 years old, were donated by the Singapore Botanic Gardens Archives from the collection of the early colonial botanists who worked in the region. These samples were also unadulterated, as were the samples from a 1917 Tjipetir blockFootnote 1 that remained under water until its recent discovery in 2019. The set of commercial stocks, 10 years old, was also minimally processed as ensured by the owner. The actual cultural heritage artifacts made of gutta percha, balata, and natural rubber in the early twentieth century were made available by a private collector.

The morphology of fresh latexes was imaged with optical and confocal laser scanning microscopy within a few hours after extracting the latexes from trees. The changes that occurred over time once the latex coagulated were recorded in an attempt to correlate them with the structures observed in aged samples. However, the structures found in aged material did not resemble formations found in the fresh latex.

The reported analysis focused on establishing the chemical markers unique for each isomer, which in turn can be applied to the identification of materials used in making cultural objects to guide their long-term preservation strategies. Several analytical methods were used to identify cis- and trans- polyisoprenes. Working with unadulterated latexes eliminated chemical alterations typically introduced during sample preparation. Traditionally, FTIR-ATR and Raman were used in the study of polyisoprenes; therefore, they were also utilized in this study to serve as comparative references only, and no results were reported. 1H and 13C NMR spectroscopy was the main analytical technique used in this study and reported here. It ensures unambiguous determination of the stereochemistry of gutta percha and natural rubber. The results were equally clear in the fresh latexes and in archival samples, thus establishing a base for the identification of these isomers in cultural objects.

Considering that gutta percha is not nearly as extensively studied as natural rubber, the emphasis of this report is on the characterization of gutta percha. Balata proved to be more problematic. Considering that balata has often been mentioned in bibliographic sources along gutta percha and natural rubber, the authors included analysis of fresh balata latex; however, no artifacts were available for analysis. The bibliographic and historical references were included in a general discussion, pointing out the ambiguities regarding the definition of what balata is, its role in the industry, and its contribution to the making of cultural heritage objects. The clarification of balata’s use and origin of latex in the past were the only two aspects of balata that were explored in this report.

Latexes of gutta percha, natural rubber, and balata; historical background and materials overview

Latex is produced in various parts of plants, in trunks, leaves, roots, and in some cases in fruits [2, 3, 5, 6, 10]. Latex harvested from the same tree but from a different location, such as the trunk or the leaves, shows variations in both physical and chemical characteristics, as was evident during FTIR-ATR and Raman examinations and in agreement with bibliographic sources, adding to the complexity of interpreting the analytical results. Other factors that impact the characteristics of latex are the geographic location of the plant, its age, the soil composition, the time of day when harvest occurs, and the climate, especially rainfall [10, 23, 38]

Historical records and patents issued at the turn of the 19th and in the early 20th century provide the first written descriptions of the trees that supply latexes, their habitats, harvesting, and processing methods. The latexes that gripped the attention of the West in the mid-nineteenth century were not new to the indigenous communities; natural rubber was used by the Aztecs for centuries to make balls for important ritual games and as a waterproofing material [3, 10, 11]. Malay people used gutta percha for tool handles, a practice first observed and described in Dr. Montgomerie’s writings in 1822 [3, 6]. Incidentally, gutta percha has been known in the West since the seventeenth century [11], although its useful commercial properties were yet unknown. Balata was mentioned in written sources as early as 1840 [3, 10] for use in the production of belts and as an additive to gutta percha and rubber [3,4,5]. However, no clear dating was found in any of the bibliographic sources as to a definite period of use, or decline in use, of balata. The ambiguity in regard to balata harvesting, processing and use, however, still exists, as evident in a relatively recent publication by Chen et al. in 2013 [21], where balata is listed as one of the microstructures of rubber.

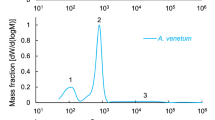

Natural latexes are colloidal suspensions of particles a few microns in size, either spherical or pear-like in shape, in a liquid. They are produced in specialized cells within a plant’s laciferous canals, as seen on scanning electron microscopy (SEM) micrographs (Fig. 1). When examined with confocal laser scanning microscopy (CLSM), the particles are clearly visible in fresh latexes and (when fresh) differ in size according to species (Fig. 2). However, these particles cannot be detected in coagulated and aged materials.

SEM–EDS micrographs and chemical mapping of stem cross-sections from two plants collected on Lingga Island, Indonesia, particle size, 4.69–11.3 microns. This agrees with botanical references indicating the presence of small and large particles in latex of the same species [16, 33]. a SEM–EDS micrograph of latex in laciferous canals in Palaquium burcki and chemical mapping of a stem cross-section showing Mg, K, Si and Ca in latex; K and Ca are considered contributors to the oxidation of latex [24,25,26], scale 200 µm. During SEM examination, the latex granules opened and combined into larger droplets, visible here as ‘blue’, round pools of fluid latex. b A cross-section of a 3-month-old seedling stem from Lingga Island, diameter of latex particles 4.69–11.3 µm; the larger appear to be clusters of smaller spheres; scale 20 µm. (Photo credit: H. Szczepanowska, 2018)

Confocal laser scanning micrographs of latex films on glass slides from tree supplying: a gutta percha (Palaquium gutta), b balata (Manilkara bidentata) and c natural rubber (Hevea brasiliensis). The images and measurements of particles were taken within 3 h after harvesting the latexes. The topography maps illustrate dispersion patterns, accumulations of particles, and their height; the warmer colors, yellow and orange, illustrate larger and taller particles, green are smaller, and blue is the base. Small particles were detected in both gutta percha and balata, 1.5–2.6 µm in gutta percha and 3.6 µm in balata; larger particles in natural rubber measured 2.7–7.6 µm; magnification 50x

There is ambiguity regarding the term ‘gutta’ in bibliographic sources; at times, it is used as a generic name of latex, and in other instances, it refers to a ‘gum’ component in latexes. The etymology of gutta percha, as explained by a linguist of Pacific languages. K. Alexander Adelaar, is in all likelihood coming from Malay ‘getah percah’, which means splattering resin' and getah'sap' or’resin’ (2019 author’s personal communication). That vernacular name hints at the chemical composition of the latexes as containing resin.

The chemical composition of gutta percha, in general terms, is indeed a mixture of hydrocarbons (gutta) and various resins, as reported in bibliographic sources [10, 25, 27]. The ratio of gutta to resin determined the quality of the final product; the higher the content of resin was, the lower the quality. That was one of the measures used by the merchants; however, no information was found as to how that ratio was determined during trading in the nineteenth century. In commercial laboratories, the content of resin in a raw sap may reach 60–70%, as reported by several authors [3, 5, 10]. A higher content of resin also lowers the melting temperature of solid gutta percha, resulting in a more rapid response of objects made of this material to the elevated temperature, altering their shapes. It has been reported that in balata, the content of resin is greater than that in gutta percha, making the final products of balata softer than those of gutta percha [7]. Other characteristics, such as gutta percha’s resistance to water and nonconductivity, were its most desired commercial properties.

The uses of gutta percha and balata were enumerated in several publications [3,4,5,6,7,8,9,10,11,12,13,14]. In the late nineteenth century, surgeons used gutta for splints and bandages, as it hardens and conforms to the shape of protected limbs; its compatibility with the human body makes it applicable in dental root canals. The ease of moulding and shaping at low temperatures made gutta percha ideal to produce commemorative plaques to capture detailed engravings of original moulds. Some of the examples that survived the passage of time, although in varied conditions, were used in this study. They are the testimony of the fleeting importance of the once household name ‘gutta’, which is now nearly forgotten.

Harvesting methods of gutta percha, natural rubber, and balata

During harvesting, the patterns of incisions and the intervals of extraction are the first indicators as to what latex is being extracted from a tree because they closely correspond to how quickly the latex of that species coagulates when exposed to air. Natural rubber flows freely for 2–3 h, balata for approximately 30 min, and gutta percha coagulates immediately upon exposure to air. The patterns of trunk incisions recorded by early Western explorers and botanists [3, 10] show that tappers were aware of the anatomy of laciferous canals in trees and how quickly the trees recovered from scoring. Consequently, the cutting patterns were distinctly different for the extraction of each type of latex (Fig. 3a, c, d). These differences were also observed during the field studies and are recorded here; the methods have only slightly changed over the years since the 19th and early 20th century published observations.

Different methods of harvesting latex: a, b natural rubber latex flows from incised bark into a cup, plantation on Langkawi Island, Malaysia. The inset in 3b shows a ceramic, glazed cup, a traditional receptacle now replaced by plastic; c, d harvest of latex from a large, over 50 m tall tree on Lingga Island, Indonesia, resembling a collection of balata [5, 10]; e, f ‘coils’ formed by rolling coagulated latex in the cut-groves, e coil, 190 mm in diameter, prepared by the tapper, 2 weeks old when imaged, overgrown by microorganisms; f fresh coil (sample LR18, used in analysis), 30 mm in diameter, was stored under water after harvest in January 2018; g large, granite stones used for maceration of leaves in Cipetir factory, Java, Indonesia, and h leaves in Cipetir plant show droplets of gutta percha latex exuding from a stem. (Images, H. Szczepanowska, 2017–2019)

The tapping of natural rubber was consistently similar in all three locations visited during the field work on the islands of Malaysia and Indonesia (Fig. 3a, b). The cutting patterns follow the tapping designed by Ridley in 1889 [23]. The latex flows to a receptacle attached at the lowest point of the cut and is emptied daily or in intervals of 2–3 days. Traditionally, the receptacle was a ceramic cup, partially glazed (Fig. 3b inset); currently, it is made of plastic.

The harvesting techniques demonstrated by a former tapper on Lingga Island, Indonesia, resembled the methods described in historical records as typical for tapping balata [2, 4], (Fig. 3c,d). The tree was incised in chevron-shape cuts, pointing downwards, cuts were spaced approximately 20–30 cm apart, and trees were tapped in 3-year intervals [3, 5, 10]. Once the latex stopped flowing approximately 20–30 min after the time of incision and coagulated, the solidified soft residue in the grooves of the cut was rolled into a ‘coil’ (Fig. 3e, f). The older methods of harvesting balata, based on early publications, were similar to collecting gutta percha, felling the tree and girdling the trunk.

Felling the trees was the predominant method of collecting gutta percha latex; it was ‘scraped’ from under the bark [3, 6, 9, 10]. Therefore, Llewellyn [6] interpreted the term ‘percha’ as ‘scraps’ in Malay, which he believed originated the name of gutta percha. (Etymology of the term was discussed earlier section).

Instantaneous coagulation of gutta percha latex was observed in CipetirFootnote 2 on Java when the tapper incised the bark for demonstration purposes; no drop could be collected because the latex solidified immediately upon exposure to air. The alternative method of extracting gutta percha latex was from macerated leaves, a method invented in 1887 by a French scientist [9] in an effort to save trees supplying raw latex from extinction. The largest commercial factory that utilized extraction of latex from leaves since around the turn of the century in the late 1900s is in Cipetir,Footnote 3 on Indonesian Island Java [ref.4] (Fig. 3 g,h). Under Dutch governance, the Indonesian name Cipetir of the plantation site was written as Tjipetir and as such was stamped on gutta percha blocks produced there and distributed commercially. According to the current custodians of the factory in Cipetir, the last recorded large-scale extraction was in 2015. The large granite stones used for macerating leaves are at standstill, and the factory is falling into disrepair, as observed during a November 2018 visit (Fig. 3g).

Research aims

The aim of this work was to characterize and identify objects made of different stereoisomers of polyisoprene. The different molecular structures govern distinct aging patterns; natural rubber becomes tacky with age, while gutta percha and balata are brittle. Establishing chemical markers to differentiate these stereoisomers from one another will aid in the accurate identification of cultural heritage objects made of these materials. This information will contribute to guiding their preservation strategies in the future. In addition to developing the analytical base for establishing a preservation protocol, the harvesting methods and processing of raw materials in remote places in Malaysia and Indonesia were recorded during the 2015–2019 field work to document rapidly disappearing regional traditions.

Materials and methods

The samples used in the analysis were collected during 4 years of fieldwork in Indonesia, Malaysia, and Singapore (2015–2019); some were donated by regional research institutes. The original artifacts were made available by collectors in the UK and Netherlands. Table 1 shows the representative samples, their provenance, labelling system that includes date of collection and age of each sample. The complete listing of samples is included in Additional file 1: (Appendix 1, Table 2), Complete Samples Set.

The four groups of samples are listed in Table 1 and include two commercial standards of pure trans- and cis-polyisoprene used as reference model compounds. The grouping of samples was based on the geographic provenance, ownership, and age of the materials. Fresh samples of plant stems were embedded in resin and polished to enable the imaging of laciferous plant cells in cross-sections.

The samples can be grouped into four distinct sets as follows:

Group I: New latex samples collected from plants during fieldwork.

Group II: 10-year-old commercial latex samples.

Group III: over 100-year-old (1892–1906) archival latex samples.

Group IV: Heritage artifacts (early twentieth century).

The materials were characterized primarily using nuclear magnetic resonance (NMR) spectroscopy. The measurements with FTIR-ATR and Raman spectroscopy traditionally applied in the rubber industry [21] were carried out for the purpose of referencing the results and comparing them with the existing bibliographic sources. Only in one instance was the comparison of Raman spectra used to illustrate the change in aged material, Fig. 11.

Materials: sample harvesting, preparation and description

The samples comprised freshly collected latex (group I), 10-year-old samples (group II), archival botanical materials, 1892–1906 (group III), and artifacts made of gutta percha (group IV). Each type of material was prepared for analysis according to its physical characteristics, yet none were intentionally altered chemically. In group I, fresh latex was cast as a thin film on microscopy glass slides. One to three drops from leaf cuttings were smeared on the slide, with one movement in one direction. In the case of latex that coagulated within 30 min on a tree, it was rolled into a ‘coil’ during harvest, as shown in Fig. 3f. The latex of gutta percha was removed as a ‘scrap’ from incisions in the tree trunk in Cipetir. In groups III and IV, the microscopic samples were removed from archival material and artifacts, approximately 0.1–0.3 g scrapings. In the 10-year-old samples, both the surface and bulk were analysed. In total, fifty samples were analysed, measured, imaged, and diagnosed. Out of fifty, the analysis of 23 selected as representative of each group is reported here. The criteria behind selecting the representative samples included well-documented provenance and origin within each group.

Group I. The sample prefixes LR, L, SG, and CI indicate the location of where the latex was harvested. The group comprises nineteen samples of fresh latexes collected between November 2017Footnote 4 and February 2019 from trunks and leaves of trees growing in the wild and in rubber plantations on the Indonesian and Malaysian Islands: Lingga, Riau Archipelago (LR) Indonesia, and Langkawi (L) Malaysia. The samples of unadulterated latexes were harvested as drops from leaves of identified botanical species in the Botanic Gardens in Singapore (SG), with the guidance of the garden’s botanist. The harvested trees included Palaquium gutta (Pg), Palaquium obovatum (Po), Manilkara bidentata (Mb), Hevea brasiliensis (Hb) and Dyera costulata (Dc). The latex, slowly flowing from leaves, was cast as film on glass slides. Larger amounts, approximately 10 ml of natural rubber latex, were permitted to be collected in rubber plantations (Fig. 3b). The liquid latex, although in airtight vials, turned into a solid coagulum after several days. Two coils of fresh latex from Lingga Island (Fig. 3f, samples LR18 and LR19) were obtained in January 2018 and February 2019 and stored under water in glass containers, following the traditional method of storing gutta percha and balata [3, 5, 10].

A piece of processed gutta percha in the form of a disc, 55 mm diameter × 6 mm thick (CI 2015, Fig. 6a), was donated by the Indonesian Forest Authorities during the November 2018 trip to Cipetir. The sample label with the prefix CI refers to Cipetir, Indonesia. It was removed from a vacuum-packed, larger load, and its surface was smooth and light gray (Fig. 6b). The sample was stored in open air, and after one year, the grey colour of the surface changed to yellow, accompanied by a crystalline, resinous layer (Fig. 6 c); both the external layer and interior bulk of the disc were analysed.

The five identified samples of latex from natural rubber were donated by the Rubber Research Institute of Malaysia (RRIM), Selangore, Malaysia (Additional file 1: (Appendix, Table 2) Complete Set, samples RRIM). The fresh latex on Petri dishes was preheated to 50 °C at the Institute prior to shipment as prevention against microbial infestation. The heat, however, changed the consistency and characteristics of the fresh latex, turning it into a translucent, tough film. The samples were measured with Raman spectroscopy and referenced when examining aged natural rubber.

Group II. The samples’ prefix SC indicates the origin, a Singapore company that distributed gutta percha. The group comprised six pieces of partially processed material intended for commercial distribution. The material according to the owner was 10 years old and collected on Lingga Island, Indonesia. In the group of six blocks, four showed resinous, mottled-color exteriors, and two had matte surfaces and resinous, crystalline in appearance interior. One of the blocks shows how the thermoplastic gutta percha and balata were shaped for shipment by pressing them into a rectangular mould, with excess material spilling over the edge and creating an uneven lip (Table 1 Group II, SC1). The partial processing involved simmering the coagulated mass in hot water to separate impurities, fragments of wood, and other particles (Dec. 2017, interview of the former distributor of gutta percha in Singapore). Next, the plastic mass of gutta percha or balata was pressed into wooden moulds. The folds of plastic material are visible on two intact blocks, as seen in expanded Additional file 1: Table S2 (Appendix I, Table S2, SC1 and SC5). Five of the 10-year-old samples and 1 fresh latex from the same location, Lingga Island, were analysed with NMR (Fig. 8).

Group III. The samples’ prefix ASG indicates their origin, Archives of Singapore Gardens. The group consisted of nine solid fragments dated from 1892 to 1906 that were part of the archival collection at the Botanic Gardens in Singapore. The microscopic samples were obtained for analysis as a courtesy of Garden’s Archivist. The specimens were collected by early botanists who studied Southeast Asian plants during the colonial period. The six samples out of this group were analysed with NMR (Fig. 9).

Group IV. The sample labels’ prefixes, CW and RS, refer to the collectors’ initials. The samples were extracted from 14 actual artworks and artifacts made of gutta percha, balata, and natural rubber from the Colin Williamson Archives, UK. The samples from six of these artifacts were analyzed (CW1-6) with NMR, and the results are shown in Fig. 10. In addition, three extractions, 2–3 mm × 1 mm diameter, from the Tjipetir block, dated for 1917 (ref. 1), were donated by the Richard Schoevaart Collection, Netherlands (RS1-3) (Fig. 6d–f). The analytical results of RS extractions from 1917 were compared with the analysis of fresh material produced in 2015, as both came from the same factory in Cipetir, although nearly 100 years apart (Figs. 7 and 9).

Standard references used as model compounds

Two chemically pure samples of cis- and trans-polyisoprenes were used as references and referred to as model compounds. The standards of cis- and trans- polyisoprenes were purchased from ChemCruz, Santa Cruz Biotechnology, Dallas, TX 75220. Cis-polyisoprene, sc-493781, Lot: D2718; trans-polyisoprene, sc-493783, Lot: D2718 Additional file 1: (Appendix 1, Table S2 Complete Sets of Samples).

Analytical methods

The cis- and trans-stereochemistry of the polyisoprene samples were analysed using the NOESY1D NMR method. The results are reported for all 23 examined samples. Additional measurements were collected with Fourier transform infrared spectroscopy coupled with attenuated total reflectance (FTIR-ATR) and Raman spectroscopy. These measurements were mainly compared with bibliographic references [35, 36]; therefore, only selected results are reported. All NMR spectra were compared with those obtained from the model compounds for trans- and cis- polyisoprene and with the available published references [21, 27, 31, 33, 34, 37].

The morphology of fresh latexes and topography of aged materials were examined with confocal scanning laser microscopy (CLSM) and field emission scanning electron microscopy coupled for chemical analysis generated by energy dispersive X-ray spectroscopy (FESEM-EDS).

NMR measurements

The samples were dissolved in deuterated chloroform (CDCl3), which is typically used in preparing analytes for NMR measurements. One- and two-dimensional NMR spectra were acquired at 25 °C on a Varian INOVAUnity 600 MHz spectrometer equipped with a 5 mm broadband PFG probe. The operating frequencies at 599.67 MHz and 150.79 MHz were for proton and carbon, respectively. Sample concentrations were 5–15 mg/0.7 mL in CDCl3. The 1H NMR chemical shifts are reported in relation to the residual solvent peaks at δ 7.26 for CDCl3. The 13C NMR chemical shifts are reported in CDCl3 relative to the central peak of the triplet as it was set to 77 ppm.

Fourier transform infrared spectroscopy with attenuated total reflectance (FTIR-ATR)

Infrared spectra were collected from samples in groups I-III using an Agilent Cary 670 spectrometer with Pike MIRacle and ATR diamond accessory. The IVth group of samples from heritage objects, RS (3) and CW (6), was measured using a DigiLab UMA600 with a PIKE Gladio ATR accessory. In both cases, the spectra were averaged from 256 scans at a 4 cm-1 spectral resolution in the 3000–300 cm−1 range. The measurements were repeated three times for each set of samples at a different location on each one. The samples were measured without any preparation under ambient conditions. The FTIR Agilent Cary 670 was flushed with dry air during the entire operation. The liquid nitrogen cooled mercury cadmium telluride (MCT) detector when MIR measurements were carried out. The data were processed with the Agilent KnowingAll BioRad database.

Raman spectroscopy

Raman spectra were recorded using a Renishaw, InVia Qontor spectrometer. Two lasers were used, 785 nm at 0.5–5% laser power (set at the laser source and not on samples) for most samples. For the archival samples in group III, a less energetic 1064 nm laser was used. The spectra were collected in the range of 100–3500 cm−1 at 5–10 s accumulations of scans using a Renishaw Centrus OC4E55 detector and processed with WiRE software.

Field emission scanning electron microscopy coupled with X-ray energy dispersive spectroscopy (FESEM-EDS)

The surface morphology of fresh plant material on the cross-sections of stems was examined using field emission scanning electron microscopy, FESEM, Hitachi SU 5000, in BSE mode at 5 kV-15 kV in VA 60 Pa. The chemical distribution of elements in latexes was analysed with X-ray energy dispersive spectroscopy (EDS) and processed with Bruker software, generating chemical maps (Fig. 1a).

Confocal laser scanning microscopy

The morphology and surface topography of fresh latexes were imaged and measured with an Olympus LEXT confocal laser scanning microscope (CLSM) with a 405 nm laser source and an average number of scans of 900–4000, captured with a CCD camera at 50 × and 100 × magnifications (Fig. 2).

Results and discussion

NMR spectroscopy

Nuclear magnetic resonance spectroscopy is a powerful analytical technique that identifies stereochemistry in different molecular environments. NMR spectroscopy of polyisoprene was reported as early as 1962 (Golub et al.) [28]. However, at that time, the reports did not offer an accurate determination of trans-polyisoprene due to the low resolution of the available NMR instruments (Loadman) [27]. Another reason was a lack of access to ‘true trans’- material, as noted by Golub (1962), and a difficulty in ‘resolving the spectra’, as stated by Loadman (1998). Zaper and Koening in 1987 [29] reported on the NMR of cis-polyisoprene while examining the degree of rubber vulcanization. No comprehensive analysis of unadulterated natural latexes using NMR spectroscopy has been reported thus far.

This report illustrates how the 1H and 13C NMR spectra were generated and analyzed. The model cis- and trans-polyisoprene were generated by using one- and two-dimensional NMR techniques such as NOESY1D, gHSQCAD, and gHMBCAD. The 1H NMR spectra of samples from Groups I-IV were compared with the spectra of model compounds (Figs. 7 and 9).

The results presented in this study are based on the analysis of unadulterated material, identified as latexes of cis- and trans- and compared with the model compounds, pure trans- and cis-polyisoprenes. The NMR spectra were obtained from the surface and bulk of the fresh and naturally aged material.

One of the goals of this research was to show that despite the natural aging processes, in samples 10 and 100 years old, the characteristic spectral determination of cis and trans can be detected using NMR spectroscopy. Consequently, these identifying spectral features can determine which objects were made of gutta percha and which were made of natural rubber. Not having any examples of objects made of balata, it is not possible at this time to make a statement as to how they would be different from gutta percha. Based on the NMR spectra of natural, fresh latex, balata showed the presence of spectral features characteristic of gutta percha, such as trans- and double peaks in the region 1.92–2.10. A detailed analysis of NMR spectra is offered for representative samples for each group in heritage objects and compared with pure model material (Figs. 4, 5, 6, 7, 8 and 9).

Gutta percha from Cipetir (Tjipetir in Dutch) in 2015 and 1917 shows different degradation of surfaces exposed to air in new samples (6a–c) and old samples immersed under water (6d–f), indicating a correlation between the degradation and storage conditions. Figure 6a–c, fresh material Cipetir, 2015, exposed to air, and Fig. 6d–f, a century old material stored under water since 1917, (Tjipetir), found on the Netherland seacoast around 2019. (Photo credits: 6 d R. Schoevaart, Netherlands, with permission; 6a–f, H. Szczepanowska)

The 1H NMR spectra of gutta percha from Tjipetir 1917 (RS1-RS3) and fresh latex from Cipetir (CI 2015) show characteristic spectral features for trans-polyisoprene, confirming gutta percha. Even though samples RS1-RS3 were from 1917, the block remined under water, which protected it against exposure to oxygen. The new material from the same factory, produced in 2015, was exposed to air and showed the presence of oxidation products. Regardless of the samples’ age, 1917 and 2015, all spectra indicated gutta percha, showing a double set of peaks at 1.95–2.10 ppm for the CH2 groups. An inset in the upper part shows the molecules’ stereochemistry related to the position of the functional group in a molecule of trans-polyisoprene

Group III, samples from the Botanic Gardens Archives, Singapore, dated 1892–1901, with inset at the top showing stereochemistry of cis-polyisoprene of the model compound. The identification labels on the left follow the samples’ archival inventory (51 med, 51 small, etc.) and year inscribed by the botanists-collectors (1892, 1900, etc.). The.1H NMR spectra of the archival specimens indicated an abundance of most likely oxidation products, in addition to the main, indicative peaks in the 2.01–1.75 ppm region. Only one sample showed the characteristic peaks of cis (1892, 51 small) pointing to natural rubber, while all other are trans-polyisoprenes, characterizing gutta percha. This agreed with the information recorded on the collector’s label included with the specimen Additional file 1: (Appendix I, Table 2, Complete Set)

To the best of our knowledge, the stereochemistry of model materials (cis- and trans- polyisoprenes) has not been studied based on NOESY1D spectra and using DPFGSENOE pulse sequences. In fact, the stereochemical assignment of CH3 and H3 protons unambiguously can be established only by NOESY1D spectra (Figs. 5, 6, 7 and 8). In cis polyisoprene, the H3 and CH3 protons share a cis relationship based on the observed NOE when the double bond H3 proton was excited at 5.12 ppm Additional file 2: (Appendix 2, Figs. 1, 2, 3, 4, 5 and 6). However, selective excitation of H3 at 5.12 for trans polyisoprene did not reveal that CH3 protons (H3 and CH3) share a trans-relationship.

For clarity of reporting, a stacked format of the 1H NMR spectra of model compounds was added to spectra from heritage objects, as shown in Fig. 7 (for trans-) and Fig. 9 (for cis-).

The 1H NMR spectra of cultural heritage objects in CDCl3 solution displayed spectral features similar to those observed for cis and trans in model polyisoprenes. The typical 1H NMR chemical shift ranges in samples are as follows: (5.11–5.12 ppm, H3), methylene (1.98– 2.07 ppm, CH2), and methyl protons (1–60-1.68 ppm, CH3). The additional peaks indicate the existence of impurities that should be considered oxidation products. The polymer chain of the polyisoprenes (cis or trans) is expected to undergo an oxidation process over time; the CH3 and CH2 protons can be oxidized to produce different groups such COOH or CH2OH, and the double can be oxidized to give poly alcohol intermediates. The structure of the impurity species, however, could not be unambiguously determined by NMR techniques due to their very low concentration in the solution.

The presence of the degradation products was particularly apparent in the spectra of the archival material over 100 years old (Fig. 9). Interestingly, the same complexity of the spectra was also consistent when comparing a degraded surface of the new samples from Cipetir 2015 (top surface) when the bulk of that sample, under the surface, was not changed, CI2015 (bulk) (Figs. 6c and 7).

Another set of samples from the same geographic location yet extracted 10 years apart was analysed with NMR. The 10-year-old set was a commercial stock of bocks (SC) in 2008, and new latex was collected in 2018. Both old and new materials came from Lingga Island (LR), Indonesia. Again, regardless of the natural aging of the material, all samples clearly showed the presence of trans-polyisoprenes based on their characteristic peaks (Fig. 8).

Similar to the previously mentioned comparative analysis, the spectra from the model material were compared with spectra from the archival botanical samples to determine which were gutta percha, balata, or natural rubber (Fig. 9). The brittleness or distinct tackiness of the samples was a physical demonstration of the aging characteristics of gutta percha or balata and natural rubber, respectively. The characteristic spectral features of trans- or cis-polyisoprene were clearly shown in the NMR spectra of over 100-year-old samples (Fig. 9).

The NMR spectra of the actual artifacts made of polyisoprenes from Group IV are shown in Fig. 10. Despite the materials’ age, clear and strong spectra were obtained, indicating what isomer, trans- or cis- was used in their making.

The spectra from cultural heritage artifacts, Group IV. The.1H NMR spectra indicated that gutta percha was used in making the cherub (CW1), an assembly of figures (CW7), an ink well with Three Monkeys (CW13), and the medallion (CW14). They clearly show the double peaks that characterise trans-polyisoprene. Natural rubber was identified in two balls, CW8 and CW9. The sample darker in color, CW9, showed a much greater amount of degradation products than CW8

FTIR-ATR and Raman spectroscopy

The main purpose of IR spectroscopic analysis was to compare the results with up-to-date bibliographic sources that attributed isomers as either natural rubber, balata, or gutta percha. The spectra were collected from samples in all four groups of material, compared with model compounds of pure cis- and trans-polyisoprenes and analysed in light of published references.

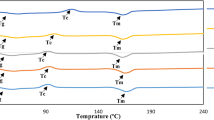

Both FTIR and Raman provide only a very general determination of whether the material is a polyisoprene; however, no specific band could be attributed to cis- or trans-isomers. One reason is that the trans isomer exists in two crystalline modifications, α at room temperature and β when heated, even if only to 50 °C; each form shows different IR spectral bands. The characteristics of α and β microstructures were studied by Nikitin and Volchek as early as in 1966 [18]. Others, Gavish et al. 1987 [30], Tanaka et al. 1990 [20], and most recently Du et al. 2019 [19], followed the same path. The latter cited author included a discussion about the ambiguity of α and β spectral determinations when relying on FTIR measurements, pointing out that the results are impacted by sample preparation, introducing chemicals and physical factors such as stretching, and exposure to elevated temperature.

Although all samples were measured with FTIR-ATR and Raman, only one set of IR spectra is included here (Fig. 11) for samples from Cipetri/Tjipetir 1917 and 2015 that were also measured with NMR (Fig. 7). The comparison of spectra generated by FTIR and Raman with NMR showed ambiguity. Furthermore, the IR spectra in the bibliographic reference listed for trans- in the region 890–885 cm-1, specifically at 865 cm-1, [18, 32, 33, 35, 36] which could not be confirmed here.

The IR spectra generated with Raman of the known gutta percha samples processed in the same factory, 100 years apart; Tjipetir (dated 1917: samples RS1, RS3) /Cipetir (CI2015, top and bulk), and model trans-polyisoprene. The peaks assigned by researchers as characteristic of trans-polyisoprene in the regions 800–900 cm−1 and 1100–1200 cm −1 are present in most samples but are not dominant, as the literature suggests

CLSM and FESEM-EDS

The morphological and topography analysis was undertaken in the very fresh latex aiming to trace the changes in aged latexes in turn correlating them with materials’ aging. The colloidal nature of fresh latexes was documented within 3 h of harvest using CLSM (Fig. 2). The FESEM examination was carried out 4 months from the date of harvest. The morphology of fresh latexes of gutta percha, balata and natural rubber analysed with CLSM revealed the characteristic granularity of a colloid that can be observed only in fresh latexes and could not be detected in the aged samples. For that reason, CLSM and SEM micrographs were used mainly in the introductory part of this report to illustrate the nature of lactiferous cells and the formation of latex in cells.

Conclusions

The analysis of natural polyisoprenes is challenging not only because they are products of complex biosynthesis in plants but also due to the chemical changes resulting from processing these materials. Considering that very limited references are available on NMR spectroscopy of polyisoprene isomers, this report offers the first thorough evaluation and unambiguous determination of the trans- and cis-stereochemistries of natural polyisoprenes using the NOESY1D NMR technique. The analysis reported here, carried out on unadulterated fresh latexes and archival, naturally aged material, provides accurate spectroscopic measurements of natural polyisoprenes. Furthermore, the authors established chemical markers of isomers that can be used in the identification of cultural heritage objects. The 1H NMR spectroscopy offers a conclusive determination of the chemical structure of natural rubber as cis- and gutta percha as trans- clearly distinguishing the material regardless of their age.

A recommendation regarding the storage of gutta percha objects was drawn from the examination, spectroscopic measurements, regional practices, such as storing semiprocessed material under water, and observation of material aging when exposed to air. This was particularly evident when analysing the samples from Tjipetir/Cipetir in 1917 and 2015 in various modes and assessing the deleterious impact of exposure to air. Based on that, it is proposed that storage in oxygen devoid conditions would be the only viable option for extending the life of artifacts made of gutta percha.

Considering the complexity of natural polyisoprenes, the authors hope that the reported research will spark further analysis.

Availability of data and materials

Data are included in the narrative and in the Supplement.

Notes

The Tjipetir blocks washed ashore of the European coast: Cacciottolo, Mario (1 December 2014). "Tjipetir mystery: Why are rubber-like blocks washing up on European beaches?". BBC News, accessed on Nov 2019. https://www.bbc.com/news/magazine-30043875 The Japanese ship Myazaki Maru was sunk on May 31, 1917 by German submarine U-88. It carried cargo of gutta percha, among other non-specified items.

The etymology of the words Cipetir and Tjipetir was elucidated by the local forest specialist during the author’s visit to Cipetir, Nov. 2018.

Nov 2017, personal communication with the chairman of Cotra Co. Singapore, which processed latex from Lingga Island, Riau Archipelago, Indonesia until 2010.

The dates of establishing the factory in Tjipetir are inscribed on the building as 1885–1921. The year 1921 marked completion of the building’s expansion according to the Indonesian officials who accompanied the author during the Nov. 2018 visit to Cipetir, Java, Indonesia. However, according to several bibliographic sources, the extraction of gutta from leaves was implemented around 1900 [2, 7, 8].

References

Smith JP. Plants and civilization; an introduction to the interrelationships of plants and people. Arcata: Humboldt State University; 2006.

Tantra IGM, Tonanon N, Lemmens RHMJ, Klaasen R, Manilkara Adans. In: Soerianegara, I and Lemmens R.H.M.J, editors. Plant Resources of South-East Asia No 51; 1993. Timber trees; major commercial timbers. PROSEA Foundation, Bogor, Indonesia, Database record: prota4u.org/prosea.

Van der Laaan JW, Production of gutta-percha, balata, chicle and allied gums. In: Bureau of Foreign and Domestic Commerce, Washington DC., Public domain, Hathi Trust, 1927, Accessed Nov 2019.

American Gutta Percha Company. Gutta percha: its discovery, properties, capabilities and uses. New York, 1848. Public domain, Hathi Trust, Accessed Dec 2019.

Llewelyn W. Laticiferous plants of economic importance, I. sources of Balata, Chicle Guttapercha and Allied Guttas. Econ Bot. 1962;16(1):17–24.

Llewelyn W. Laticiferous Plants of Economic Importance, V. Resources of Gutta-Percha. Palaguium species (Sapotaceae). US Department of Agriculture, Crops Resources Division, Beltsville, MD; Nov 28, 1962; p. 5–26.

Balata. Scientific American, a division of Nature America, Inc.:53. No.9, August 29, 1885; p.133.

Balata Gum. Scientific American, a division of Nature America; November 2, 1878: 39 (18): p.282.

Godfrey H. Submarine telegraphy and the hunt for gutta percha, challange and opportunity in a global trade global economic series. Leiden: Utrecht University Koninklijke Brill; 2018.

Clouth F. Rubber, Gutta-Percha and Balata, MacLaren & Sons, London, D. van Nostrand Co, New York, (the 1st publication in German 1873 and 1879, published by B.F. Voigt, Leipzing); 1903.

Heardick D. Gutta-Percha: a case of resource depletion and international rivalry, IEEE Technology Society Magazine, Dec. 1987; 12–16.

Seeligmann T, Lamy Torrilhon G, Falconnet H. Indiarubber and gutta percha, a complete practical treaties on indiarubber and gutta percha in their historical, botanical, arboricultural, mechanical, chemical and electrical aspects. London; 1910.

Kent EG, Swinney FB. Properties and applications of trans-1,4 polyisoprene. IEC Prod Res Dev. 1966;5(2):134.

Hosler D, Bukett SL, Tarkanian MJ. Prehistoric polymers: rubber processing in ancient mesoamerica. Science. 1999;284:1988–90.

Gilbert M. Plastics materials: Introduction and historical development. In: Gilbert M, editor. Brydson’s plastics materials. Amsterdam: Elsevier Science & Technology; 2016.

Guru Sakar Rajan, Trans-1,4, Polyisoprene In: Polymer Data Handbook. Oxford University Press Inc: 1999. p. 620–624.

Bunn CW. The stereochemistry of the rubber molecule. Rubber Chem Technol. 1942;15(4):704–8.

Nikitin VN, Volchek BZ. A study of conformational transformation in gutta percha by infrared spectroscopy Zhurnal Prikladnoi Specytroskopii. J Appl Spectrosc. 1966;14(6):546–53.

Du A, Liu K, Yang L, Zijun Gu. Comparison of crystallization behaviour of trans-1,4 polyisoprene under different crystallization temperature, pressure and tension. J Polym Res. 2019;26:172.

Tanaka Y, Mori M, Takei A, Boochathum P, Sato Y. Structural characterization of naturally occurring trans-polyisoprenes. J Nat Rubb Res. 1987;5(4):241–5.

Chen H, Shao W, Huang YB. Fourier transform spectra analysis of polyisoprene of different microstructure. Int J Polym Sci. 2013;2013:1.

Wei X, Peng P, Peng F, Dong J. Natural polymer eucommia ulmoides rubber: a novel material. J Agric Food Chem. 2021;69:3797–821.

Malaysian Rubber Board (MRB), Rubber Plantations and Processing Technologies, A Statuary Agency under the Ministry of Plantation Industries and Commodities. Tingkat 17&18, Bangunan Getah Asli, Kuala Lumpur, Malaysia, 2009.

Cornish K. Biochemistry of natural rubber, a vital raw material, emphasizing biosynthetic rate, molecular weight and compartmentalization, in evolutionarily divergent plant species. London: The Royal Society of Chemistry; 2001.

Memmler K. The science of rubber, Handbuch der Kautschukwissenschaft. New York: Reinhold Publishing Corporation; 1934.

Tuampoemsab S, Sakdapipanich J, Tanaka Y. Influence of some non-rubber components on aging behaviours of purified rubber. Rubber Chem Technol. 2006;80:159–69.

Loadman MJR. Analysis of rubber and rubber-like polymers. 4th ed. London: Kluwer Academic Publishers; 1998.

Golub MA, Fuqua SA, Bhacca NS. High resolution nuclear magnetic resonance spectra of various polyisoprenes. J Am Chem Soc. 1962;84:4981–2.

Zaper AM, Koenig JL. Solid state carbon-13 NMR studies of vulcanized elastomers. II, sulfur vulcanization of natural rubber. Rubber Chem Technol. 1987;60(2):252–77.

Gavish M, Brennan P, Woodward AE. Infrared spectral correlations for crystalline and amorphous trans-l,4-polyisoprene. Macromolecules. 1988;21:2075–9.

Sutherland GBM, Vallance JA. The application of polarized Infra-red radiation to problems in molecular structure, I. Ann Arbor, Michigan: Polyisoprenese, University of Michigan; 1950.

Adam C, Lacoste J, Lemaire J. Photo-oxidation of polyisoprene. Polym Degrad Stab. 1991;32:51–69.

Arjunan V, Subramanian S, Mohan S. Fourier transform infrared and Raman spectral analysis of trans-1,4-polyisoprene. Spectrochim Acta Part A. 2001;57(13):2547–54.

Jackson KDO, Loadman MJR, Jones CH, Ellis G. Fourier transform Raman spectroscopy of elastomers: an overview. Spectrochim Acta Part A. 1990;46(2):217–26.

Tennent NH, Caen J, Courtney P, Lozano E. In situ Raman spectroscopic characterization of polymers used in past conservation treatments. e-Preservation Science, 6. 2009; 107–111. http://www.morana-rtd.com/epreservationscience/2009/Tennent-01-07-2008.pdf, last checked 23.02.2018.

Cornell SW, Koenig JL. Raman spectra of polyisoprene rubbers. Macromolecules. 1969;2(5):546–9.

Bunce SJ, Edwards EGM, Johnson AF, Lewis IR, Turner PH. Synthetic polyisoprenes studied by Fourier transform Raman spectroscopy. Spectrochim Acta Part A. 1993;49(5–6):775–83.

Bonner J, Galston AW. The physiology and biochemistry of rubber formation in plants, vol. 13. New York: Botanical Review. Springer on behalf of New York Botanical Garden Press; 1947. p. 543–96.

Acknowledgements

Gratitude is extended to the Rubber Research Institute of Malaysia (RRIM), Rubber Research Institute of Indonesia (RRII), and the Hi-Tech company, Selangore, Malaysia, for their support. The authors are grateful to staff of the Singapore Botanic Gardens for taxonomic identification of trees, invaluable information about their collection and samples of raw and archival material. Thanks are due to collectors Mr. Colin Williamson, UK, and Richard Schoavaart, Netherlands, for their generous donation of samples and permission to use the images of artifacts from their collection. Thanks are due to D. Lizun, Senior Conservator at HCC for assistance with embedding the plant material for cross-section examination.

Funding

Self-funded.

Author information

Authors and Affiliations

Contributions

Both authors wrote and checked the narrative. Dr. AN carried out NMR analysis, and HS carried out FTIR, CLSM, Raman. Both authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1.

Appendix 1: Table 2, A complete set of samples that were analyzed in this study with information on the provenance, geographical location of where the samples were collected, their age, and harvesting processes.

Additional file 2.

Appendix 2: Spectra generated by NMR with detailed calculation of cis- and trans-positions used in determining if a material is a natural rubber or gutta-percha.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Szczepanowska, H.M., Akhmedov, N.G. Gutta percha, natural rubber and balata-chemical characterization of polyisoprenes in the context of cultural heritage. Herit Sci 11, 125 (2023). https://doi.org/10.1186/s40494-023-00954-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-023-00954-z