Abstract

In the 1870s, dentures were one of the first products made with celluloid, the first semi-synthetic plastic. Despite the significance of denture development in the history of celluloid and plastics, the chemical characterization of dentures in museum collections has never been attempted. It is urgent to assess the extent of celluloid heritage in denture collections due to the high degradation risk that this material imposes. In this work, 21 dentures from the National Museum of American History and from the Dr. Samuel D. Harris National Museum of Dentistry were characterized using a multi-analytical methodology using handheld Raman, X-Ray fluorescence, and micro-Fourier transformed infrared spectroscopies. All dentures were successfully characterized: 12 are made of celluloid, 4 of vulcanized rubber, 2 of phenol–formaldehyde, 2 of polyvinyl chloride—polyvinyl acetate copolymer (PVC-PVAc) and 1 of polymethyl methacrylate (PMMA). The identification of the dentures’ base materials allowed a better understanding of their history and posed new questions about their conservation. Handheld Raman was demonstrated as an excellent in-situ tool for the study of polymeric materials.

Similar content being viewed by others

Introduction

Developed in the USA in 1870 by John Wesley Hyatt, celluloid is a thermoplastic material composed of cellulose nitrate and camphor. Considered the pioneer of the plastics industry, celluloid was prized for its remarkable capacity to imitate natural materials, such as ivory or tortoiseshell. The advent of synthetic plastics eventually led to the gradual loss of celluloid’s importance due to technical and economic reasons [1, 2]. Celluloid objects are now testimonies to a unique historical period: the transition from a society dependent on natural materials and their limitations to a society that synthesizes materials according to its needs. Today it can be difficult to identify this material: sometimes confused with the natural material it imitates; other times classified under the general term of plastic. While “hidden” in heritage collections, celluloid creates a problem: this material is inherently unstable, prone to degradation by the action of light, water, or heat, leading to the complete loss of the object’s integrity, to the oxidation of materials by nitrous and nitric acid (HNO3) and, potentially, to health problems [3,4,5,6,7,8,9,10,11,12,13]. Therefore, it is imperative to promptly identify the presence of celluloid in cultural heritage artifacts, and through examination of their history and degradation characteristics, develop sustainable methodologies for their preservation and exhibition.

The first successful use of celluloid was in the manufacture of billiard balls. The second was in the making of dentures. Hyatt introduced celluloid in the denture market in the early 1870s to challenge vulcanized rubber [1]. Despite the significance of celluloid dentures in the history and development of plastics, there is lack of material culture and conservation science studies that consider dentures in museum collections. However, several studies have been made on the history and chronology of materials used for dentures [14,15,16,17,18,19,20]. This creates a knowledge gap between the history of denture materials and the dentures that reside in the collections. This gap results in an extreme difficulty for museums in identifying the composition of dentures dated from the late nineteenth—early twentieth centuries, due to the variety and similar properties of the materials used by the industry. The problem extends to the interpretation, exhibition, and conservation of dentures. This is because the definition of the dentures' composition is essential in delineating their cultural significance, comprehending their physical–chemical changes over time, and determining the most suitable techniques for their preservation [13].

In this work, this issue is addressed by the analysis of two collections of dentures from the National Museum of American History (NMAH) and from the Dr. Samuel D. Harris National Museum of Dentistry (NMD) using a multi-analytical approach consisting of handheld Raman X-ray fluorescence (XRF) spectrometers and micro–Fourier Transformed Infrared spectroscopy (µFTIR).

Overall, our results demonstrate the importance of a spectroscopic approach to the identification of the materials that exist in denture collections. The identification of five different materials, namely celluloid, vulcanized rubber, phenol–formaldehyde plastic, polyvinyl chloride—polyvinyl acetate (PVC-PVAc) copolymer and polymethyl methacrylate (PMMA), broadened the understanding of these denture collections and posed new questions about their conservation.

In the next section, a brief historical overview of the development of dentures from the eighteenth to the twentieth centuries is presented. The chemical analysis of the dentures provided new information about the impact of different formulations and manufacturing methods on celluloid stability, on camphor substitution due to the bad taste and smell and on vermilion substitution due to toxicity.

Brief historical overview of the materials used in dental plates—from vulcanite to PMMA

In the eighteenth century, denture makers used ivory bases with human teeth, but both materials deteriorated in the mouth. In 1776, Alexis Duchateau and Dubois de Chémant invented a method to produce porcelain dentures that fitted well in the mouth and were aesthetically pleasing. However, no other dentist could replicate this process due to the unpredictable shrinkage of porcelain during firing. This led to the discontinuation of complete porcelain dentures by 1814. At this point, ivory dentures were still used, and gold was one of the preferred materials in denture making. However, both materials were costly, and the manufacturing methods were lengthy and complex. In 1844, the discovery of nitrous oxide as an anesthetic gas by Wells, allowing the painless extraction of teeth, increased the demand for dentures [14].

Charles Goodyear was granted a patent for the manufacture of vulcanite (vulcanized or hard rubber) dentures in 1855 [14]. Vulcanite was a cheap material, compared to ivory or gold, and allowed the enlargement of the dental plate market in the nineteenth century. It could be easily molded to the shape of the mouth with accurate surface detail. Still, vulcanite had problems: the natural color of vulcanized rubber is brown and very high quantities of vermilion (mercury (II) sulfide, α-HgS) were mixed to tentatively imitate the natural red color of the gums; it was a porous material leading to staining and cleaning problems [1, 14, 15]. Until 1881, the Goodyear company charged expensive fees to dentists who used vulcanite due to patent rights, leading them to search for alternatives. However, after the expiration of the patent in 1881, vulcanite became “universally employed” [21]. Vulcanized gutta-percha, known as corallite, was also used for dental plates. Edwin Truman introduced it in 1851, but it was considered unstable, becoming brittle over time [15, 21].

Parkesine was the first cellulose nitrate plastic, invented in England by Alexander Parkes and introduced to the market during the 1860s [1]. Daniel Spill took an interest in Parkesine’s potential and founded, with the inventor, a company with an initial capital of £10,000—the Parkesine Company Ltd. This company was unsuccessful and was liquidated in 1868, possibly due to these reasons: the use of low-quality raw materials, such as scraps of paper or rags, leading to a product with a “dirty” appearance; the flammability of the material; the use of large proportions of solvents combined with an insufficient drying process, leading to product deformation; and failure to conquer specific markets [1, 22,23,24].

John A. McClelland made the first attempt to use cellulose nitrate as a base for dentures in the 1860s [25]. In 1868, he patented dental plates using collodion mixed with gum copal, coloring matter, and an additive to reduce inflammability, namely ammonium phosphate, cadmium iodide or calcium oxalate [26]. This dental plate base was known as “Consolidated Collodion” or “Rose-Pearl”. Advocated as being a superior base to vulcanite, some opposed it due to material shrinkage—“Rose-Pearl is pretty, but it shrinks” [27]. Considering the problems of Parkesine due to the high quantity of solvents used, it is possible that Rose-Pearl suffered from the same difficulties.

John Wesley Hyatt solved the solvent problem by mixing cellulose nitrate and camphor by mechanical means. He patented this innovative process in 1870 and, with his brother, Isaiah S. Hyatt, called this material “Celluloid”. Celluloid had the advantage of being a thermoplastic material, meaning it becomes pliable above its glass transition temperature and solid upon cooling [camphor acts as a plasticizer for cellulose nitrate, decreasing its glass transition temperature (Tg) and increasing its flexibility; the secondary Tg of pure cellulose nitrate and celluloid (cellulose nitrate + 29% wt. camphor) are circa 100 °C and 53 °C, respectively [28, 29]). This process can be repeated any number of times. Therefore, Hyatt was able to sell pre-made forms, the dental blanks, to manufacturers, who then used them to mold the dentures under heat and pressure from the mouth impressions of the patients. This strategy of distributing celluloid in pre-made forms, namely sheets, rods, and tubes, would eventually become the marketing strategy that led to its success. It was an advantage over vulcanite, a thermoset polymer that could not be reheated. Vulcanite denture manufacturers had to proceed with the vulcanization reactions themselves in apparatus called vulcanizers.

The formulation used by the Celluloid Manufacturing Company was 1 part of celluloid to 0.04 parts of vermilion [30]. Vulcanite dentures looked dull and unnatural due to their brown color and high vermilion content [48 parts of rubber to 36 parts of vermilion [21]]. Celluloid, on the other hand, had a truly natural appearance. Celluloid was so esthetically close to human gum that it prompted S.S. White Dental Mfg. Co. to create a set of artificial teeth that better resembled human, a line called “natural forms” [25]. However, celluloid was more expensive than vulcanite and had stability problems, leading to color and dimensional changes. Furthermore, the taste of camphor was widely considered unpleasant [1].

In the nineteenth century, celluloid dentures were sold by the Celluloid Manufacturing Company and the American Zylonite Company. Other tradenames for celluloid dentures appeared in the twentieth century, such as Alcolite and Hecolite (invented in 1925), sold by the Alcolite Inc. and by the American Hecolite Denture Corporation, at least until the 1930s, Additional file 1: Figures S1 and S2.

Both vulcanite and celluloid were far from meeting the requirements for a perfect denture material. Therefore, with the advent of synthetic plastics, new materials were introduced in the denture market in the twentieth century. In 1927, the Dental Manufacturing Company Limited, London, started using Walkerite, a phenol–formaldehyde product. In 1933, the Bakelite Corporation introduced a material called Luxene. Several other phenol–formaldehyde dentures were commercialized, but these dentures showed color and dimensional change problems [18]. Vinyl dentures, made of mixtures of PVC and vinyl acetate started to be sold in 1932. S.S. White sold Resovin, marketed as “the highest quality denture material”, Additional file 1: Figure S3. Unfortunately, these vinyl dentures showed breakage problems in the mouth and fell into disuse [18]. The best replacement for vulcanite only appeared in 1936, with the commercialization of Vernonite, a polymethyl methacrylate (PMMA) denture [16]. This material fulfilled all the dental plate requirements and rapidly dominated the market. In 1938, a survey of dental plate materials used by dentists showed that 71% used vulcanite, 20% phenol–formaldehyde, 8% cellulose derivates and 1% vinyl resins. In 1947, another survey concluded that 95% of all dentures were made of PMMA [14].

The manufacturing processes of celluloid dentures

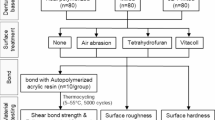

There were three processes to mold dentures from the celluloid blanks: the oil-glycerin bath, the steam apparatus, and the “dry-heat” process [30]. The Hyatt brothers invented and patented the first two in 1871 and 1874, respectively [31, 32]. In the oil-glycerin bath, as the name indicates, the celluloid blanks were placed in metallic flasks (with the mold of the mouth made in plaster) immersed in a vegetable oil or glycerin bath heated to a temperature of 150 ºC. Using the steam apparatus, the flasks were heated to a temperature between 100 and 150 ºC and the pressure was regulated by a safety-valve, Fig. 1. The first “dry-heat” apparatus for the molding of celluloid dentures is attributed to R. Finley Hunt, an American dentist, living in Washington, D.C, patented in May 1875 [33, 34]. The second “dry-heat” apparatus was probably the one patented by Ferdinand Heindsmann, assignor to S.S. White, in July 1875 [35]. This apparatus had the advantage of also being a vulcanizer and manufacturers could use it for either celluloid or rubber. The “Heindsmann’s heater” was a dry oven in which the flasks with celluloid were heated to a temperature of 135 °C with an alcohol lamp [36], Fig. 1.

A Scheme of the steam apparatus patented by the Hyatt brothers in 1874 [32]. B Sectional view of the celluloid steam apparatus manufactured by the Celluloid Manufacturing Company and sold by S. S. White Dental Manufacturing Company [36, 37]. C Example of one of these steam machines, collection of the National Museum of American History, catalog number M-08954. D Scheme of the "dry-heat" apparatus patented by Ferdinand Heindsmann, assignor to S.S. White, in 1875. E Patent model, NMAH collection, catalog number M-04242. F "Heindsmann’s heater” was manufactured and sold by S. S. White Dental Manufacturing Company in 1876 (Catalogue of dental materials, furniture, instruments, etc., for sale by Samuel S. White) [36]

Although S.S. White Dental Mfg. Co. was granted in 1874 the exclusive right to sell the celluloid base, in 1878 the Celluloid Manufacturing Company distributed a pamphlet exposing the disadvantages of the “dry-heat” process, which was “manufactured by other parties” [30, 36]. The problems presented were the uneven heating of the dental blank and the need to use a wet plaster. In 1876, the “Heindsmann’s heater” was sold at $12 while the Hyatt´s steam apparatus was sold at $15. The possibility of acquiring a 2 in 1 celluloid and rubber apparatus at a lower price was a better deal for the dental plate makers [21]. The Celluloid Manufacturing Company's need to send a message explaining their products' superiority is thus understandable.

In 1879, John S. Campbell, from New Jersey, invented an apparatus that superseded the previous ones, as pointed out by dentists in technical books [21, 34, 37]. It became known as the “New Mode Heater” and was also a vulcanizer. This apparatus had an outer compartment with steam to heat the dry inner chamber with the flasks. John Campbell combined the advantages of Hyatt’s and Heindsmann’s apparatus: the use of steam for a uniform heating and a dry chamber to avoid contact of celluloid with steam (which had a negative effect on color and porosity). Other devices of the same type were invented later, namely the W. W. Evan´s and Seasbury’s vulcanizers [38, 39], the latter being commercialized by S.S. White Dental Mfg. Co. in 1894 [40].

An outcome of the “New Mode Heater” was that it allowed the development of vulcanite dentures with celluloid gums and porcelain teeth. This method became known as the “New Mode Continuous Gum” [16, 21]. For aesthetics, the vulcanite dentures could be covered with artificial gums made of porcelain, which also had a very natural look. However, this was a very difficult technique [15]. The “New Mode Continuous Gum” offered a more straightforward method using the same apparatus for molding vulcanite plates and veneering with celluloid.

In the 1920s and 1930s, the processes used were like the ones of the nineteenth century. For example, in a technical book for Hecolite dental plate manufacture, the apparatus described—the “Hecolizer”—was very similar to the Hyatt’s steam apparatus, with the difference of being built in aluminum and having an 110 V electric heater [20].

The vermilion problem

Vermilion (mercury (II) sulfide, α-HgS) was one of the most important red pigments until it stopped being produced in the twentieth century due to toxicity concerns [41]. Vermilion could be made by grinding mineral cinnabar or synthesized by the “dry” or “wet” methods. The wet method was invented in Germany in the seventeenth century by heating the black solid-phase form of mercury sulfide (metacinnabar, β-HgS) in a solution of ammonium and potassium sulfide. This process became the favorite in Europe and the USA [42]. Vermilion is a pigment known for its strong hiding power and high chroma. This pigment was blended with white pigments, such as lead or zinc white, to produce pink hues commonly used for flesh tones [42].

The use of this pigment in vulcanite and celluloid dentures raised the suspicion of mercury poisoning. The toxic effects were attributed to the liberation of mercury by the action of saliva [43]. The worry of mercury poison led the Celluloid Manufacturing Company to advertise that celluloid had the advantage of only needing small amounts of vermilion compared to vulcanite [30]. The debate on vermilion toxicity in dentures extended to dentistry journals: Niles’s (1881) opinion was that it could be prejudicial if the pigment derived from impurity-rich cinnabar by the existence of poisonous free mercury; high purity vermilion, synthetized by the “wet-process”, would not cause any harm to the user. For him, the reason why celluloid and vulcanite led to problems in the mouth was related to the low heat conductivity of these materials compared to metals, thus his preference for metal plates [44]. Johnstone (1883) and Globenski (1889) maintained that vermilion was not harmful and added that cleanliness of the denture was a crucial factor in affecting the user’s mouth health [45, 46]. The increasing concerns about vermilion toxicity in the twentieth century led to the invention of a celluloid formulation for dentures without vermilion. Hecolite was produced using a “a non-poisonous aniline instead of the toxic vermilion” [20]. It is unknown if any other products without vermilion were produced. In the twenty-first century, it was shown that α-HgS can be absorbed by the gastrointestinal tract and distributed to several tissues, including the brain [47]. Both the dry and wet synthesis processes can produce vermilion containing free mercury; the latter process in lower concentrations [48].

Due to its importance as an artistic material from antiquity to the nineteenth century, vermilion has been extensively studied [49,50,51,52,53,54,55]. Vermilion can darken if exposed to UV light by phase conversion of the red α-HgS to the black β-HgS. It was shown that chloride can act as a catalyzer of the light breakdown of α-HgS to metallic mercury (Hg), also leading to color changes. Raman spectroscopy was demonstrated as a technique with the potential to assess vermilion degradation by the shift and broadening of its characteristic peaks [51].

Aims of this research

The primary objective of this research was to characterize the formulations and conservation conditions of celluloid dentures. Consequently, the 21 dentures subjected to analysis in this investigation were chosen based on two criteria: (1) they were labeled as celluloid (NMD and NMAH), or (2) they were composed of an unidentified material yet exhibited comparable visual characteristics to those recognized as celluloid (NMD).

Due to camphor’s undesirable odor and taste, celluloid dentures were an ideal case study to ascertain the extent to which camphor substitutes had been used to counteract this issue. Although camphor was considered the best cellulose nitrate plasticizer, several alternatives were tested from the 1880s to the 1920s. In addition to its unpleasant odor, camphor had other problems: its high melting point (175 °C), meaning that great care was required to apply the temperatures necessary to combine it with cellulose nitrate; the price fluctuations imposed by the Japanese monopoly; and World War I supply shortages [13, 24, 56]. John Henry Stevens, the chief chemist of the Celluloid Manufacturing Company, started experimenting in the 1880s, testing several fragrant additives such as oil of cinnamon leaves or oil of wintergreen. In 1894, he patented acetanilide as a valid substitute for camphor: acetanilide had a melting temperature of 112ºC and was odorless [24, 57, 58]. Later other chemicals were patented as total or partial camphor substitutes, such as oil of turpentine, triphenyl phosphate, or phthalates [13, 56,57,58,59,60,61].

Due to the concerns regarding the toxicity of vermilion and technical records mentioning the manufacture of celluloid dentures without vermilion, it was also useful to understand how vermilion was used and replaced in historical dentures.

Handheld Raman spectroscopy was used for the in-situ molecular characterization of the polymer matrix. To support the identification of cellulose nitrate, camphor, vermilion, and zinc oxide (the most common filler/stabilizer used in celluloid formulations), references of these materials were analyzed previously to the historical dentures. Micro sampling and microFTIR were performed on selected celluloid dentures to complement the formulation characterization and assess the conservation condition by quantifying the cellulose nitrate degree of substitution (DS) using calibration curves [62]. The degree of substitution of cellulose nitrate is defined as the number of nitrate groups attached per monomer (maximum of 3). Therefore, the quantification of the DS is an infrared tool to assess the polymer conservation condition since the decrease of DS (from 3 to 0) correlates with the scission of the nitrate group, i.e., degradation. According to the literature, the DS used to manufacture celluloid articles was 2.2 [63]. When the dentures were not made of celluloid, microFTIR was used to confirm the in-situ characterization made by handheld Raman. Portable XRF was used in-situ on the NMAH dentures to gain elemental information on inorganic additives, namely the fillers and pigments, such as zinc oxide and vermilion.

This work also provides insights into the materials used for the dentures’ teeth. Because teeth were not the focal point of this research and due to analysis time restrictions, only one tooth of 6 different celluloid-labelled dentures was analyzed with handheld Raman spectroscopy.

Experimental

Collections from NMD and NMAH

This work analyzed 21 dentures, 15 from NMD and 6 from NMAH. Of NMD’s 15 dentures, 5 were on display and described with a label (4 identified as celluloid and 1 as cellulose acetate; identification method unknown) and the other ten were in storage and their materials unidentified. JUSTI 21, 23 and 24 were in the permanent exhibition and SSW 19 and 21 were in the exhibition “Tools of the trade: ancient Japanese dentistry” compiled by Dr. John Littlefield during an 1890–1892 world tour to introduce S.S. White Dental Manufacturing Company products to Australia and Asia. NMD’s dentures were analyzed by handheld Raman. Microsampling and µFTIR were performed on 5 celluloid dentures based on their Raman spectra, dates, and conservation conditions. NMAH’s 6 dentures were selected based on their prior celluloid labelling. They were in storage and were analyzed using handheld Raman, µFTIR and XRF.

Materials

The following materials were used as Raman and infrared material references: Pure cellulose nitrate membranes (Amersham™Protran®, 0.2 µm), camphor (96%, Sigma-Aldrich), zinc oxide (ZnO, Sennelier), vermilion (α-HgS, May & Baker LTD), PMMA sheet (unknown supplier), phenol–formaldehyde billiard ball (Aramith), 87% PVC- 13% PVAc copolymer (Aldrich Condensed Phase library, CAS number 9003-22-9) and calcium stearate [64].

Preparation of celluloid reference

A solution of 2% w/w of cellulose nitrate in methanol was prepared at room temperature and allowed to dissolve through the night (approx. 12 h). Cellulose nitrate-camphor (celluloid) films were obtained by adding camphor to the solution of 2% w/w cellulose nitrate in methanol. Camphor was added in 30% w/w to cellulose nitrate. Camphor was allowed to dissolve through the night (approx. 12 h). The solution was cast homogenously over the surface of a microscope glass slide using a Pasteur pipette. The microscope glass slides were placed inside a desiccator with silica-gel and the solution left drying through the night (approx. 12 h). After drying, transparent cellulose nitrate-camphor (celluloid) films were obtained.

Characterization with handheld Raman spectroscopy

Handheld Raman spectra were acquired using Metrohm Raman MIRA DS. This Raman spectrometer operates with a diode laser with an excitation wavelength of 785 nm (100mW) and has a 200–2300 nm spectral range. The equipment provides a spectral resolution of 8–10 cm−1 and a spot size between 0.04 and 2.5 mm. The detection technique is Orbital Raster Scan (ORS). The ORS scans a large area of the sample surface with a tightly focused beam that maintains a high spectral resolution, an advantage for heterogeneous materials and without putting the material surface at risk [65]. In this work, the laser power was set at maximum intensity (power 5) and with the maximum scans allowed by the software (10 scans) to obtain the best signal-to-noise ratio. The integration time was adjusted according to the response of the analyzed material, between 4 and 10 s. The measurements were collected using the 3 mm distance objective setting, i.e., without touching the object, Additional file 1: Figure S4. Variations in the microscale of the objective distance can be applied to increase the signal–noise ratio. For this purpose, a micrometric precision tripod (2 µm precision), with manual fine XYZ positioning, designed for MIRA DS was used. Sample curvature effects were minimized by testing different distances and positions and probing the spectrum intensity [66]. Cellulose nitrate, camphor, diethyl phthalate, zinc oxide and vermilion references were previously analyzed and supported the identification of these compounds, by comparison. Also, references for PMMA, using a sheet available at the laboratory (unknown supplier), and for phenol–formaldehyde resin, using a phenol–formaldehyde billiard ball (Aramith, made by Saluc, Belgium), were analyzed. Celluloid, cellulose acetate, polymethyl methacrylate (PMMA) and polyvinyl chloride (PVC)were also identified based on the literature [10, 60, 67,68,69].Raman data for phenol–formaldehyde plastics (bakelite) or hard rubber (ebonite or vulcanite) identification was supported on [70, 71].

Characterization with µFTIR

Microsample acquisition

Microsamples were acquired from selected NMD and NMAH dentures using Ted Pella μ-tools. At NMD for magnification, a Dino-Lite digital microscope with magnification range 10x–50x, 230 × and 640 × 480 0.3MP image resolution was used. A M8 Wild Heerbruug stereomicroscope (6 × to 50 × magnification) was used at NMAH. The dentures and sampling locations are shown in the Additional file 1: Figure S5 and Table S1.

Micro Fourier Transform Infrared Spectroscopy (µFTIR)

Infrared spectra were acquired on a Nicolet iS50 FT-IR spectrophotometer equipped with a Nicolet Continuμm (15 × objective) microscope and a Mercury–Cadmium–Tellurium (MCT) detector cooled by liquid nitrogen. Micro samples were placed on a DC-3 diamond compression cell (Specac) and the spectra were acquired in transmission mode between the 4000–650 cm−1, with a resolution of 8 cm−1 and 128 scans. Spectra are shown as acquired, without corrections or any further manipulation, except for removing the CO2 absorption at approximately 2300–2400 cm−1 using OMNIC software. The degree of cellulose nitrate substitution was calculated using a calibration curve developed by Nunes et al. [62]. Celluloid, PVC—PVAc copolymer, PMMA and beeswax identification was based on the OMNIC spectra library and literature [10, 72, 73]. The analysis of the spectra obtained from the hard rubber and phenol–formaldehyde dentures was more complex. Although identifying these materials can be made based on the literature [72, 74,75,76,77], it is difficult to understand what information can be extracted from the spectra. There is a lack of comprehensive work in the field of conservation science that explains the infrared spectral variations observed in the hard rubber and phenol–formaldehyde historical objects that may be related to synthesis or manufacturing differences, composition, or degradation. This problem has already been emphasized by Bell et al. [74].

Characterization with handheld X-Ray fluorescence spectroscopy

A portable/handheld X-ray fluorescence spectrometer S1 Titan from Bruker, from NMAH’s National Numismatic Collection group, was used for the on-site elemental analysis, Additional file 1: Figure S6. Experimental parameters used were voltage of 40 kV, current of 6μA and acquisition times between 5 and 20 s. The elements were identified by their characteristic X-ray emission lines using ARTAX software.

Results and discussion

Reference spectra by MIRA DS

Two intense bands characterize cellulose nitrate Raman spectrum at 853 and 1284 cm−1 attributed to the nitrate group stretching vibrations. Other bands from the nitrate groups are observed at 625, 699 and 1656 cm−1. The bending vibrations of the CH and CH2 groups are observed at 1371 and 1456 cm−1, respectively. The bands observed between 1000 and 1215 cm−1 are assigned to the cellulosic acetal structure, i.e., the ring ether and the glycosidic bond. The camphor spectrum is characterized by several bands, the most intense at 652 cm−1 being attributed to the ring deformation of this compound. In the celluloid spectrum, the cellulose nitrate bands are influenced by camphor: in the region between 200 and 800 cm−1 with the observation of the strong camphor band at 649 cm−1; changes in the region between 900 and 1200 cm−1; observation of two bands additional at 1414 and 1453 cm−1; and the observation of a band at 1732 cm−1 due to the camphor carbonyl group, Fig. 2A [10, 60, 67]. Vermilion is characterized by three bands at 256, 285 and 344 cm−1; zinc oxide by bands at 285, 332, 386 and 439 cm−1, Fig. 2C.

A Raman spectra of a cellulose nitrate reference (Amersham™Protran® membrane), camphor (96%, Sigma-Aldrich) and celluloid (cellulose nitrate + 30% wt camphor). B Cellulose nitrate and camphor chemical structures. Cellulose nitrate is showed with a degree of substitution 2 (on average, two nitrate groups and one hydroxyl group per monomer). 2. C Raman spectra of vermilion (HgS, mercury sulfide) and zinc oxide (ZnO), also known as zinc white

Multinalytical characterization of NMD and NMAH dentures

All dentures, 21 in total, were successfully characterized: 12 are made of celluloid, 4 of vulcanized rubber, 2 of phenol–formaldehyde, 2 of polyvinyl chloride—polyvinyl acetate copolymer (PVC-PVAc) and 1 of polymethyl methacrylate (PMMA).

Celluloid dentures

Handheld Raman and µFTIR provided a straightforward identification of celluloid by detecting characteristic cellulose nitrate and camphor absorption bands. In the Raman spectra, all celluloid dentures (12 in total) showed similar absorptions: the three intense nitrate band vibrations around 1650, 1280 and 840 cm−1, the glycosidic structure vibrations between 1250 and 1000 cm−1, and the camphor carbonyl stretching at 1730 cm−1, C-H stretching and bending vibrations between 3000 and 2800 and 1500–1300 cm-1, respectively, Fig. 3 and Tables 1 and 2. Raman spectra of JUSTI 24 and MG.M-09686 showed additional bands at 1043, 1596, 1603 and 1040, 1579, 1597 cm−1, respectively, and a shift of the carbonyl bands to lower wavenumbers, Fig. 3. These features are characteristic of a phthalate plasticizer. Phthalate plasticizers started to be used in the 1920s, thus the Raman data correlates with the date proposed for JUSTI 24 (1930s). Phthalate bands were not observed in the infrared spectra, only a shift of the carbonyl band to lower wavenumbers was detected, Tables 1 and 2.

Raman spectra of celluloid (cellulose nitrate + camphor) dentures acquired with handheld Raman, using different acquisition times: JUSTI 24, 14 s acquisition time; MGM-09686 (denture 1 (black) and 2 (blue)), 3.5 s; 2002.99.5780, 6 s; SSW21, 10 s. Vermilion and phthalate peaks are highlighted in red and green, respectively

All celluloid dentures showed the presence of vermilion (HgS) in the Raman spectra, Fig. 3, Table 1 and 2 and Additional file 1: Figure S7. The first band of vermilion shifts from 263 to 256 cm−1 depending on the object, which can be related to pigment degradation. In the case of the MG.M-09686 set, the vermilion bands were barely visible, only confirmed by the presence of mercury (Hg) emission lines in the XRF spectra, Figs. 3 and 4. The main elements identified in this celluloid set, were zinc (Zn) and mercury (Hg). In the red gums of two vulcanite dentures, MG.291116.0049 and MG.291116.0046, Zn and Hg were also identified as the main components, Fig. 4. It was possible to observe a higher intensity of the emission lines of Zn and Hg in the vulcanite dentures, indicating the higher concentration of these elements in comparison to celluloid. It was also observed that the concentration of Hg to Zn was higher in the vulcanite dentures, Fig. 4.

XRF spectra of celluloid dentures MG.M-09686 (dentures 1 and 2) and vulcanite dentures MG.291116.0046 and MG.291116.0049, normalized to the maximum (corresponding to Zn Kα emission line). A higher relative intensity of vulcanite's Hg emission lines is observed. The analysis points are marked in the images of the dentures

In the case of denture JUSTI 21, the microsamples acquired were very superficial, resulting in an unexpected infrared result, the identification of beeswax. This material could have been used to block celluloid camphoric taste, or it is a residue from a beeswax impression of the mouth (used until the 1880s by some dentists) [21], Fig. 5A and B. The identification of celluloid by handheld Raman shows the capability of this technique to detect materials at greater depths and avoid superficial coatings.

A Photographs of dentures JUSTI 21, JUSTI 24 and SSW21, with indication of teeth analyzed with handheld Raman. B Infrared spectra of JUSTI 21 beeswax coating. C Raman spectra acquired from the porcelain teeth of JUSTI 21 (black, 1.2 s, 1 scans) and JUSTI 24 (red, 14 s, 10 scans) and from the human teeth of SSW21 (blue, 7 s, 10 scans)

The degree of substitution of cellulose nitrate was calculated with infrared spectroscopy for 7 dentures, Tables 1 and 2. In the MG.M—09686 set, the dental blank showed a higher DS (2.11) than the dentures 1 and 2 (1.98 and 1.92). This decrease from one form to the other (dental blank to dental plate) can be related to the degradation induced by molding process (considering that in this case, they are all made from the same raw celluloid batch). The dental blank shows a DS value close to the stated by the literature for the manufacture of raw celluloid (2.2) [62]. The lower value (2.11) can be related to ageing but also to the initial process of transforming the celluloid sheet into a dental blank.

From the 7 plates, dental plate 2002.99.5780 was the one in worst visual conservation condition, with brown areas across the red gums and yellowed teeth with dark spots, Table 2 and Additional file 1: Figure S9. This dental plate showed the lowest DS value (1.87), which correlated with the visual observation. Denture 92.2.0924 showing localized dark spots associated to a pitting effect (possibly due to a technique to achieve a more natural imitation of the gums) had a DS of 1.96, Table 2 and Additional file 1: Figure S10. Dental plate JUSTI 24 (1930s), SSW21 (1890–1892) showed DS of 2.03 and 2.12 respectively, Table 2. According to the dates proposed for these dental plates, it would be expected for JUSTI 24 to be in better conservation condition than SSW19. This emphasizes the presence of the phthalate plasticizer, which might be accelerating the degradation of celluloid (the same goes for the MG.M–09686 set). Recently, it was shown that diethyl phthalate accelerates cellulose acetate degradation but for celluloid this investigation as yet to be carried out [78, 79]. Lower DS can also be related to the cellulose nitrate manufacturing quality: phthalate plasticizers could be added for the manufacture of lower quality products. Lower manufacturing quality is also associated to the presence of residual sulfates due to an inadequate washing process, accelerating celluloid degradation [5, 6, 13].

Handheld Raman analysis of the celluloid dentures’ teeth

The tooth of denture SSW21 was identified as a human tooth by the detection of the characteristic hydroxyapatite peaks at 432 ν2(PO), 583 ν4(PO), 961 ν1(PO43−) and 1071 cm−1 ν1(CO32−) [65], Fig. 5 and Table 2. All the other teeth analyzed in this work with handheld Raman were identified as porcelain teeth by the detection of broad bands between 1100 and 2200 cm−1, characteristic of the luminescence of rare earth elements when using a NIR excitation source to analyze glasses and ceramics [80], Fig. 5, Tables 1 and 2 and Additional file 1: Figure S11. In the case of dentures JUSTI 24, SSW19 and MG.M–09686 (dentures 1), it was possible to also identify the characteristic peak of α-quartz (SiO2) at 460 cm−1. Recently, it was demonstrated that the broad luminescence bands above 1100 cm−1 are due to the presence of glaze layers and their spectral profile change depends on the processing temperatures [81]. JUSTI 21 porcelain tooth showed better-resolved bands compared to the other dentures’ porcelain teeth, which suggest a different manufacturing method, Fig. 5.

Vulcanized rubber dentures

There were four dental plates, NMD’s Kellmer 95 and 2002.99.4797 and NMAH’s MG.291116.0046 and MG.291116.0049 where no peaks were observed in the Raman spectra. Kellmer 95 and 2002.99.4797 dental plates are very identical to each other having a dark brown color. MG.291116.0046 and MG.291116.0049 are also very identical in the appearance of the gums, an heterogenous red mixture. All four were identified as vulcanized rubber, or hard rubber, by µFTIR, Fig. 6 and Table 3. The most characteristic bands of this compound are the CH2 and CH3 stretching vibrations between 2930 and 2850 cm−1 and bending vibrations at 1450–1375 cm−1. However, several spectral differences were found in the four objects. Different fillers were identified: barium sulfate (BaSO4) was identified in Kellmer 95 by its characteristic bands at 1185, 1119, 1087 and 984 cm1; this filler was also identified in the dark red of denture MG.291116.0046. Calcium carbonate was found in 2002.99.4797 by the bands at 876 and 712 cm−1 (the broadening of 1449 cm−1 is due to this compound which has a strong absorption at 1430 cm−1). All vulcanized rubber dental plates exhibit a band at 1710–1705 cm−1, which can be due to oxidation or due the presence of an additive. Broad bands between 1700 and 1500 cm−1 suggests the presence of proteins.

Infrared spectra acquired from the dentures identified as vulcanized rubber, by the detection of bands in the CH stretching (3000–2800 cm−1) and bending regions (1450–1375 cm−1). Denture 2002.99.4797 has porcelain gums. Dentures MG.29116.0046 and 0049 were micro sampled in different regions due to color differences, a dark and a light red, which showed spectral variations

Denture MG.291116.0046 metal plate is a nickel–chromium-based alloy by identification with XRF. The dark red area of this denture showed a complex X-ray fluorescence spectrum, with several bands attributed to zinc, selenium, strontium, cadmium, barium, and sulfur, Table 3 and Additional file 1: Figure S12. Sulfur is from the vulcanized rubber structure. Barium correlated with the identification of barium sulfate by infrared spectroscopy. In the future, other complementary techniques may provide more information on the zinc, selenium, cadmium, and strontium compounds.

Polyvinyl chloride—Polyvinyl acetate copolymer (PVC-PVAc) dentures

NMD’s dental blank 2002.99.5831 was manufactured using Resovin, sold by S.S. White, Fig. 7A. With handheld Raman it was possible to identify the main peaks of PVC at 638, 695, 1115, 1334 and 1432 cm−1,. A similar spectrum was obtained for MG.291116.0061, a denture previously identified as celluloid, Fig. 7C and Table 4.µFTIR provided more information; both were identified as PVC-PVAc copolymer. PVC main bands are observed at 1431 cm−1 attributed to the angular deformation of CH2-Cl, at 1238 cm−1 to the CH-Cl out of plane angular deformation, between 1100 and 1025 to the C–C stretching, at 967 cm−1 to the C-H out of plane deformation; and at 831 and 692 cm−1 to the C–Cl stretching. PVAc is identified by its main bands at 1739 cm−1 of the carbonyl stretching and 1370 cm−1 of the CH3 bending vibration [82]. The PVC-PVAc copolymer identified in both dentures has a higher PVC content compared to PVAc, by comparison with the A1370cm−1/A1238cm−1 band ratio of an IR reference spectrum of 83% PVC:17% PVAc copolymer, Fig. 7D and Table 4. The low content of PVAc is probably why handheld Raman was not able to identify bands from this polymer.

A Dental blank 2002.99.5831 and detail of the inscription where it is possible to read “S.S. White Resovin. Trademarks. Rec. in U.S. Pat. Off. and elsewhere. Made in U.S. of A.”; B XRF spectrum of MG.291116.0061, showing the strong emission of chloride. C Raman of dental blank 2002.99.5831 (black, 4 s, 10 scans) and denture MG.291116.0061 (blue, 3 s, 10 scans). D Infrared spectra of dental blank 2002.99.5831 (black) and denture MG.291116.0061 (blue), compared to a reference spectrum of 83% PVC:17%PVAc copolymer (grey)

Both dentures 2002.99.5831 and MG.291116.0061 showed two additional infrared bands at 1575 and 1542 cm−1, Fig. 7D and Table 4. These two bands, correlated with the sharp CH2 assymetric and symmetric stretching bands at 2915 cm−1 and 2850 cm−1, indicate the presence of calcium stearate, a lubricant and stabilizer for PVC, Additional file 1: Figure S13 [83].

Denture MG.291116.0061 was analyzed by XRF and chlorine (Cl) was found, correlating with the identification of PVC, Fig. 7B. According to Rueggeberg (2001) “By 1932, mixtures of PVC and vinyl acetate were available for use as denture base materials”. This result shows that Resovin was one of these mixtures [16].

Phenol–formaldehyde dentures

In the case of dental plate 2002.99.5459, a difficult-to-read inscription was found, being distinguishable the first three letters “LUX” and the last letter “E”, Fig. 8B. The identification of the material as a phenol–formaldehyde resin, by the observation of Raman main bands at 1296 (CH2 twisting), 1453 (CH2 bending), 1610 cm−1 (ring stretching) and other minor bands, and by comparison with a phenol–formaldehyde resin billiard ball (Aramith), allows us to deduce that it is a Luxene dental plate manufactured by the Bakelite Corporation, Fig. 8A and C. Dental plate 2002.99.5524 was also identified as a phenol–formaldehyde but no inscriptions were found, Fig. 8C Table 5. Denture 2002.99.5459 was also analyzed by infrared spectroscopy, validating the material characterization as a phenol–formaldehyde plastic, namely by the observation of bands between 1600 and 1300 cm−1 from the benzene ring stretching, the CH2 asymmetric and symmetric stretching at 2921 and 2864 cm-1, the C = C stretching between 3100 and 3000 cm-1 and the OH stretching with maximum at 3359 cm−1, Table 5 and Additional file 1: Figure S14.

A Advertisement of Luxene, Bakelite Corporation, circa 1940 (J. Harry DuBois Collection on the History of Plastics, NMAH.AC.0008). B Photography and detail of the top of the denture 2002.99.5459 where the inscriptions “LUX” and “E” are read. C Raman spectra of dentures 2002.99.5459 (black, 9 s, 10scans), 2002.99.5524 (blue, 3 s, 1 scan) and a phenol–formaldehyde Aramith billiard ball (grey, 8 s, 1 scan)

Polymethyl methacrylate (PMMA) denture

JUSTI 23, previously identified as cellulose acetate, was identified as PMMA by the observation of its main bands at 599 (C–C–O stretching), 813 (C–O–C stretching), 1451 (CH bending) and 1728 (carbonyl stretching) cm−1 and other minor bands, correlating with the Raman spectrum of a PMMA reference, Fig. 9. Raman was performed at both the transparent top and red gum area with the same results. With infrared spectroscopy, PMMA was also identified by the detection of characteristic bands from 2994 to 2844 the stretching vibration of the CH3 and CH2; at 1730 cm−1 the carbonyl stretching; between 1485 and 1385 cm−1 deformation of the CH2 and CH3; between 1300 and 950 cm−1 vibrations of the ester group; and at 841, 751 cm−1 skeletal vibrations [75], Table 6 and Additional file 1: Figure S15.

Conclusions

This work demonstrates the significance of celluloid in the denture market between the 1870s and the 1940s. The review of celluloid denture history shows that this material was an option aesthetically superior to vulcanite and easier to manufacture than porcelain. Patients who wanted a natural imitation of flesh and had the money for it could acquire a celluloid denture or a vulcanite/metal denture with celluloid gums. Celluloid impacted the development of denture manufacturing apparatus and induced the creation of new styles of porcelain teeth. Methods for making celluloid dentures were explained in several technical books, and prominent sellers sold the celluloid dental blanks in America and in Europe, namely S.S. White Manufacturing Company and Claudius Ash & Sons Company, respectively.

We demonstrate the importance of identifying the materials that exist in the collections of dentures. This approach broadened the understanding of celluloid denture history and the collections studied. The associations between material and appearance are now more evident. Five different materials were characterized in the collections of the National Museum of American History and the Dr. Samuel D. Harris National Museum of Dentistry: celluloid (12 dentures), vulcanized rubber (4 dentures), phenol–formaldehyde plastic (2 dentures), polyvinyl chloride—polyvinyl acetate copolymer (2 dentures) and polymethyl methacrylate (1 denture). All these materials represent different historical and physical experiences and conservation approaches. Special attention goes to the high number of celluloid dentures observed, which validated the importance of this material in denture development and commercialization. The high percentage of celluloid dentures identified in this collection, in contrast to the 1938 survey where cellulose derivatives constituted only 8%, suggests a larger use of celluloid dentures before the 1930s. However, it is necessary to consider that the dentures analyzed in this study were specifically selected based on their probability of being made with celluloid.

Collections worldwide holding historical dentures must pay attention to the presence of celluloid due to the risk of degradation and acid attacks. Signs of cellulose nitrate degradation include discoloration, brittleness, cracking, or weeping [72, 84, 85]. Yet, the celluloid dentures studied in this work are primarily in good conservation condition. They all showed similar compositions of cellulose nitrate, camphor, and vermilion. Those analyzed with XRF showed the presence of zinc, likely zinc oxide, which has a stabilizing effect on celluloid [5, 6]. The only formulation change appears to be the addition of phthalate plasticizers in the 1920s, probably to replace camphor partially. Calculation of the degree of substitution of cellulose nitrate suggests that the phthalate plasticizer may accelerate celluloid degradation or be associated to lower quality materials. Denture manufacturing processes can also play an essential role. References should be produced following the historical formulations and aged to assess the degradation mechanisms and propose conservation guidelines.

Given the descriptions of complaints due to the bad taste and smell of camphor in celluloid dentures, it was interesting to observe that all celluloid dentures had camphor in their composition. This is not unexpected, as camphor was always considered the best plasticizer for cellulose nitrate. Furthermore, camphor may potentially yield beneficial outcomes owing to its antiseptic and antifungal properties. However, the impacts on the user's well-being necessitate further investigation given concerns surrounding its toxicity [86]. In the future, it would be useful to see if coatings, like beeswax, play a role in blocking taste, even though beeswax's presence is likely a vestige of a mouth impression using this material. This coating may have positive conservation impacts: JUSTI 21 is in excellent conservation condition. The conservation condition of JUSTI 21 can also be associated with its manufacturing quality. This denture’s gold base is indicative of its high cost. The presence of beeswax and of unique porcelain teeth can also be markers denoting a product of exceptional quality.

Due to the discussions in the late nineteenth century about vermilion problems, it is also interesting to observe the ubiquity of vermilion in celluloid dentures, especially regarding the dentures dated from 1920s onward (plasticized with phthalate compounds). Based on the XRF results, vulcanized rubber dentures showed a higher concentration of vermilion than celluloid, in accordance with the technical literature of the late 19th-early twentieth century. Efforts were being made to replace vermilion in celluloid, but no substitutes were found. Other colorants appear to be used in the synthetic plastics, not by their identification but by the absence of vermilion bands in the Raman spectra. Chloride can act as a catalyst of vermilion degradation, a possible reason for its disuse in PVC-PVAc dentures.

Handheld Raman was demonstrated to be an excellent in-situ technique in identifying all the dentures’ base materials, except for the vulcanized rubber (also known as vulcanite or hard rubber). In this case, identification was only achieved using µFTIR. Handheld Raman was able to identify the phthalate plasticizers in celluloid dentures JUSTI 24 and MG.M-09686, dating them between the 1920s and the 1940s, from the start of phthalate plasticizer industrial use until the appearance of PMMA (which superseded all the previous materials). These phthalates were not detected by µFTIR, showing how powerful handheld Raman spectroscopy is in detecting these additives.

Finally, we note that a systematic investigation of the vulcanized rubbers, phenol–formaldehyde, and polyvinyl chloride—polyvinyl acetate copolymer plastics should be performed. Only with a detailed study of the manufacturing processes and analysis of references will it be possible to extract more information from the spectroscopic data. In this work, it was possible to correlate tradenames with the material characterization: Resovin from S.S. White with a PVC-PVAc copolymer; and Luxene from the Bakelite Corporation with a phenol–formaldehyde resin.

Availability of data and materials

All data generated or analyzed during this study are included in this published article (and its supplementary information files).

Abbreviations

- DS:

-

Degree of substitution

- NMAH:

-

National Museum of American History

- NMD:

-

National Museum of Dentistry

- ORS:

-

Orbital Raster Scan

- PMMA:

-

Polymethyl methacrylate

- PVAc:

-

Polyvinyl acetate

- PVC:

-

Polyvinyl chloride

- XRF:

-

X-Ray fluorescence spectroscopy

- µFTIR:

-

Micro–fourier transformed infrared spectroscopy

References

Friedel R. Pioneer plastic: the making and selling of celluloid. Madison: The University of Wisconsin Press; 1983.

Meikle JL. American plastic: a cultural history. New Bunswick: Rutgers University Press; 1997.

Thérias S, Bussière PO, Gardette M, Gardette JL, Lattuati-derieux A, Lavédrine B, et al. Degradation of celluloid in art works: a study of the mechanisms. Actes du colloque Sciences des matériaux du patrimoine culturel. 2012;2:68–73.

Bussiere PO, Gardette JL, Therias S. Photodegradation of celluloid used in museum artifacts. Polym Degrad Stab. 2014;107:246–54.

Quye A, Littlejohn D, Pethrick RA, Stewart RA. Investigation of inherent degradation in cellulose nitrate museum artefacts. Polym Degrad Stab. 2011;96:1369–76.

Quye A, Littlejohn D, Pethrick RA, Stewart RA. Accelerated ageing to study the degradation of cellulose nitrate museum artefacts. Polym Degrad Stab. 2011;96:1934–9.

Elsässer C, Micheluz A, Pamplona M, Kavda S, Montag P. Selection of thermal, spectroscopic, spectrometric, and chromatographic methods for characterizing historical celluloid. J Appl Polym Sci. 2021.

Kavda S, Micheluz A, Elsässer C, Pamplona M. Development of a gel permeation chromatography method for analysing cellulose nitrate in museums. J Sep Sci. 2021.

Valente M, Lozano C, Elsässer C, Angelin EM, Pamplona M. Shedding light on degradation gradients in celluloid: an ATR-FTIR study of artificially and naturally aged specimens. Polymers. 2023;15:522.

Neves A, Angelin EM, Roldão É, Melo MJ. New insights into the degradation mechanism of cellulose nitrate in cinematographic films by Raman microscopy. J Raman Spectrosc. 2019;50:202–12.

Neves A, Ramos AM, Callapez ME, Friedel R, Réfrégiers M, Thoury M, et al. Novel markers to early detect degradation on cellulose nitrate-based heritage at the submicrometer level using synchrotron UV–VIS multispectral luminescence. Sci Rep. 2021;11:20208.

Curran K, Underhill M, Grau-Bové J, Fearn T, Gibson LT, Strlič M. Classifying degraded modern polymeric museum artefacts by their smell. Angewandte Chemie Int Ed. 2018;57:7336–40.

Quye A. Quality matters for historical plastics: the past-making of cellulose nitrates for future preservation. Cahiers François Viète. 2017;2:45–65.

Murray MD, Darvell BW. The evolution of the complete denture base. Theories of complete denture retention a review. Part 1. Aust Dent J. 1993;38:216–9.

Engelmeier RL. The history and development of posterior denture teeth—introduction, part II: artificial tooth development in America through the Nineteenth Century. J Prosthodont. 2003;12:288–301.

Rueggeberg FA. From vulcanite to vinyl, a history of resins in restorative dentistry. J Prosthet Dent. 2002;87:364–79.

Ladha K, Verma M. Nineteenth century denture base materials revisited. J Hist Dent. 2011;59:1–11.

Smith G. Denture Bases. Australian Dental Mirror. 1939;5:14–32.

Kimball H. Modern denture base materials, and what to expect of them. J Am Dent Assoc Dent Cosmos. 1938;25:243–52.

Underdahl L. The technique for hecolite. Portland: American Hecolite Denture Corporation; 1930.

Harris CA. The principles and practice of dentistry, including anatomy, physiology, pathology, therapeutics, dental surgery and mechanism. 13th ed. Philadelphia: P. Blakiston’s Son and Co; 1913.

Yarsley VE, Flavell W, Adamson PS, Perkins NG. Cellulosic plastics. London: The Plastics Institute; 1964.

Mossman STI. Parkesine and celluloid. In: Mossman STI, Morris PJT, editors. The development of plastics. London: The Royal Society of Chemistry; 1994. p. 10–25.

Worden EC. Nitrocellulose industry. Volume II. London: Constable and Company Ltd, 1911.

A Catalog of the World’s Premium S.S. White Porcelain Teeth. Philadelphia: The S.S. White Dental Manufacturing Company; 1911.

McClelland JA. Improved Material for Forming Dental Plates. USA: USP 77304, 1869.

Wright CM. Coming Base. Transactions of the American Dental Association. 1869;67–70.

Zhanning J. The glass transition temperature measurement of nitrocellulose by torsional braid analysis. Propellants Explos Pyrotech. 1992;17:34–7.

Hamrang A. Using accelerated ageing process to predict the archival life of cellulose nitrate-based materials and historical objects. In: Haghi AK, editor. Chemistry and chemical engineering research progress. New York: Nova Science Publishers, Inc; 2010. p. 10–7.

Smith CS. Celluloid as a base for artificial teeth. Newark, New Jersey: Celluloid Manufacturing Company; 1878.

Hyatt JW, Hyatt IS. Improved Apparatus for Moulding Dental Plates. USA; USP 121522, 1871.

Hyatt IS, Hyatt JW. Apparatus and Processes For Molding Celluloids and the Coumpounds of Pyroxyline. USA; USP 152232, 1874.

Hunt RF. Process and Apparatus for Softening and Molding Celluloid. USA; 162752, 1875.

Evans WW. Celluloid and Zylonite. In: Essig CJ, editor. The American textbook of prosthetic dentistry. 2nd ed. Lea Brothers and Co: Philadelphia and New York; 1901.

Heindsmann F. Improvement in Dental Vulcanizing Apparatus. USA; USP 165328, 1875.

White SS. Catalogue of dental materials, furniture, instruments, etc., for sale by Samuel S. White. Philadelphia: The S.S. White Dental Manufacturing Company; 1876.

Gilbert SE. Vulcanite and celluloid: instructions in their practical working for dental purposes. Philadelphia: The S.S. White Dental Manufacturing Company; 1884.

Evans WW. Apparatus for forming dental plates. USA; USP 279365, 1883.

Seabury FW. Dental Vulcanizer. USA; USP 443699, 1890.

Vulcanizers, Celluloid Press, and Accessories. Philadelphia: S.S. White Dental Manufacturing Co.; 1894.

Radepont M. Understanding of chemical reactions involved in pigment discoloration, in particular in mercury sulfide (HgS) blackening. Antwerpen: Université Pierre et Marie Curie - Paris VI; Universiteit Antwerpen; 2013.

Gettens R, Feller R, Chase WT. Vermilion and Cinnabar. In: Roy A, editor. Artists’ pigments: a handbook of their history and characteristic. Volume II. Washington, DC: National Gallery of Art; 1993. p. 159–82.

Goldwater L. Mercury in dentistry. Clin Toxicol. 1991;29:151–64.

Niles ES. The compatibility of rubber and celluloid with the tissues of the mouth. Dent Cosmos. 1881;23:458–61.

Johnstone A. Sore mouths from rubber and celluloid. Items of interest. 1883;6:114–5.

Globensky S. Celluloid in mechanical dentistry. Is it to be recommended? Dom Dent J. 1889;1:162.

Yen C-C, Liu S-H, Chen W-K, Lin R-H, Lin-Shiau S-Y. Tissue distribution of different mercurial compounds analyzed by the improved FI-CVAAS. J Anal Toxicol. 2002;26:286–95.

Strahan D, Tsukada M. Measuring mercury emissions from cinnabar lacquer objects. Stud Conserv. 2016;61:166–72.

Feller RL. Studies on the darkening of vermilion by light. Rep Stud Hist Art. 1967;1:99–111.

Yu J, Warren WS, Fischer MC. Visualization of vermilion degradation using pump-probe microscopy. Sci Adv. 2019;5:eaaw313621.

Chiriu D, Pala M, Pisu FA, Cappellini G, Ricci PC, Carbonaro CM. Time through colors: a kinetic model of red vermilion darkening from Raman spectra. Dyes Pigm. 2020;2021(184):108866.

Miguel C, Pinto JV, Clarke M, Melo MJ. The alchemy of red mercury sulphide: the production of vermilion for medieval art. Dyes Pigm. 2014;102:210–7.

Spring M, Grout R. The blackening of vermilion: an analytical study of the process in paintings. Natl Gallery Tech Bull. 2002;23:50–61.

Keune K, Boon JJ. Analytical imaging studies clarifying the process of the darkening of vermilion in paintings. Anal Chem. 2005;77:4742–50.

Hogan C, Da PF. Colour degradation of artworks: an ab initio approach to X-ray, electronic and optical spectroscopy analyses of vermilion photodarkening. J Anal At Spectrom. 2015;30(3):588.

Sachs AP, Byron O. Camphor substitutes in the manufacture of celluloid. Ind Eng Chem. 1921;13(10):893–901.

Pereira A, Candeias A, Cardoso A, Rodrigues D, Vandenabeele P, Caldeira AT. Non-invasive methodology for the identification of plastic pieces in museum environment—a novel approach. Microchem J. 2016;1(124):846–55.

Mazurek J, Laganà A, Dion V, Etyemez S, Carta C, Schilling MR. Investigation of cellulose nitrate and cellulose acetate plastics in museum collections using ion chromatography and size exclusion chromatography. J Cult Herit. 2019;35:263–70.

Salvant J, Sutherland K, Barten J, Stringari C, Casadio F, Walton M. Two Làszló Moholy-Nagy paintings on Trolit: insights into the condition of early cellulose nitrate plastic. e-Preserv Sci. 2016;13:15–22.

Paris C, Coupry C. Fourier transform Raman spectroscopic study of the first cellulose-based artificial materials in heritage. J Raman Spectrosc. 2005;36:77–82.

Stewart RA. Analytical Studies of the Degradation of Cellulose Nitrate Artefacts [Doctor of Philosophy]. University of Strathclyde; 1997.

Nunes S, Ramacciotti F, Neves A, Angelin EM, Ramos AM, Roldão É, et al. A diagnostic tool for assessing the conservation condition of cellulose nitrate and acetate in heritage collections: quantifying the degree of substitution by infrared spectroscopy. Herit Sci. 2020;8:1–14.

Reilly JA. Celluloid objects: their chemistry and preservation. J Am Inst Conserv. 1991;30:145.

Otero V, Sanches D, Montagner C, Vilarigues M, Carlyle L, Lopes JA, et al. Characterisation of metal carboxylates by Raman and infrared spectroscopy in works of art. J Raman Spectrosc. 2014;45:1197–206.

Geravand A, Hashemi Nezhad SM. Simulation study of the Orbital Raster Scan (ORS) on the Raman spectroscopy. Optik. 2019;1(178):83–9.

Bowie BT, Chase DB, Lewis IR, Griffiths PR. Anomalies and artifacts in Raman Spectroscopy. In: Chalmers JM, Griffiths PR, editors. Handbook of vibrational spectroscopy. Chichester: John Wiley & Sons; 2002.

Madden O, Cobb KC, Spencer AM. Raman spectroscopic characterization of laminated glass and transparent sheet plastics to amplify a history of early aviation “glass.” J Raman Spectrosc. 2014;45:1215–24.

Kilsinska-Kopacz A, Lydzba-Kopczynska B, Czarnecka M, Kozlecki T, del Melendez JH, Mendys A, et al. Raman spectroscopy as a powerful technique for the identification of polymers used in cast sculptures from museum collections. J Raman Spectrosc. 2019;50:213–21.

Babo S, Ferreira JL, Ramos AM, Micheluz A, Pamplona M, Casimiro MH, et al. Characterization and long-term stability of historical PMMA: impact of additives and acrylic sheet industrial production processes. Polymers. 2020;12:2198.

Monni J, Niemela P, Alvila L, Pakkanen TT. Online monitoring of synthesis and curing of phenol—formaldehyde resol resins by Raman spectroscopy. Polymer. 2008;49:3865–74.

Hendra PJ, Jackson KDO. Applications of Raman spectroscopy to the analysis of natural rubber. Spectrochim Acta. 1997;50:1987–97.

Shashoua Y. Conservation of plastics: materials science, degradation and preservation. Amsterdam: Elsevier Ltd; 2008.

Derrick MR, Stulik D, Landry JM. Infrared spectroscopy in conservation science. Los Angeles: The Getty Conservation Institute; 1999.

Bell J, Nel P, Stuart B. Non-invasive identification of polymers in cultural heritage collections: evaluation, optimisation and application of portable FTIR (ATR and external reflectance) spectroscopy to three—dimensional polymer—based objects. Herit Sci. 2019;7:1–18.

de Sá SF, da Cruz SM, Callapez ME, Carvalho V. Plastics that made history—the contribution of conservation science for the history of the Portuguese Plastics Industry. Conservar Património. 2020;35:85–100.

Connors SA. Chemical and physical characterization of the degradation of vulcanized natural rubber in the museum environment. Kingston: Queen’s University; 1998.

Linnig FJ, Stewart JE. Infrared study of some structural changes in natural rubber during vulcanization. J Res Natl Bur Stand. 1934;1958(60):9–21.

Mohtar AA, Nunes S, Silva J, Ramos AM, Lopes J, Pinto ML. First-principles model to evaluate quantitatively the long-life behavior of cellulose acetate polymers. ACS Omega. 2021;6:8028–37.

Mohtar AA, Pinto ML, Neves A, Nunes S, Zappi D, Varani G, et al. Decision making based on hybrid modeling approach applied to cellulose acetate based historical films conservation fourier transform infrared spectroscopy. Sci Rep. 2021;11:16074.

Carter EA, Wood ML, Waal D, Edwards HGM. Porcelain shards from Portuguese wrecks: Raman spectroscopic analysis of marine archaeological ceramics. Herit Sci. 2017;5:1–8.

Kamura S, Tani T, Matsuo H, Onaka Y, Fujisawa T, Unno M. New probe for porcelain glazes by luminescence at near-infrared excitation. ACS Omega. 2021;6:7829–33.

Abdelghany AM, Meikhail MS, Asker N. Synthesis and structural-biological correlation of PVC PVAc polymer blends. J Market Res. 2019;8:3908–16.

Gönen M, Ozturk S, Balköse D, Okur S, Ulkü S. Preparation and characterization of calcium stearate powders and films prepared by precipitation and langmuir-blodgett techniques. Ind Eng Chem Res. 2010;49:1732–6.

Quye A, Williamson C. Plastics: collecting and conserving. Edinburgh: NMS Publishing Limited; 1999.

POPART: A European Project on the preservation of plastic Artefacts in Museum Collections. https://popart-highlights.mnhn.fr/. Accessed 31 May 2023.

Santos CD, Cabot JC. Persistent effects after camphor ingestion: a case report and literature review. J Emerg Med. 2015;1(48):298–304.

Acknowledgements

This work thanks to the Dr. Samuel D. Harris National Museum of Dentistry, namely to Patrick Cutter, and to the Smithsonian Institution, National Museum of American History, namely to Dr. Kristen Frederick-Frost, Deborah Warner, and Rachel Anderson, by granting access and supporting the study of the collections. Artur Neves thanks his Fulbright host institution, the University of Maryland, College Park, namely the Department of History, the Department of Materials Science and Engineering, and professors Philip Soergel and Ray Phaneuf for the support, working space and research tools.

Funding

Artur Neves thanks to Fulbright Portugal and to the Portuguese Foundation for Science and Technology (FCT/MCTES)] for funding this work (Fulbright grant PS00326022 and FCT doctoral grant PD/BD/136678/2018); We also thank FCT/MCTES for funding the project “The Plastics Metamorphoses—the reality and the multiple approaches to a material” (2022.05086.PTDC), and Associate Laboratory for Green Chemistry- LAQV (UID/QUI/50006/2019 and UIDB/50006/2020) co-financed by the ERDF under the PT2020 Partnership Agreement (POCI-01-0145-FEDER-007265). We thank the NEMOSINE project, 2020-NMBP‐35‐2017, grant agreement no. 76081, for supporting the transportation of Raman MIRA DS.

Author information

Authors and Affiliations

Contributions

AN, RF and MEC contributed with the conception and design of the research work; AN performed the analysis and interpretation of the Raman and infrared spectral data. SDS contributed with the selection of the historical dentures. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Figure S1.

Advertisement for Hecolite in the Evening Star, Washington, D.C, Friday, February 8, 1935. Figure S2. Advertisement for Alcolite in the Indianopolis Times, March 21, 1933. Figure S3. Resovin dental platefrom the Smithsonian Collection, ID number MG.260892.295. Figure S4. Raman MIRA DS analysis of the swaged gold and celluloid dental plate JUSTI 21 from NMD (left) and of the vulcanized rubber and Vitallium alloy denture MG.291116.0046 from NMAH (right), using the 3 mm distance objective set up. Figure S5. NMAH’s dentures and micro sampling location. Denture photographs source: Smithsonian Institution. Table S1. NMD’s denture and sampling location. The microscope images were collected with a DINO-LITE digital microscope. Figure S6. Right, celluloid denture inside the X-ray fluorescence spectrometer S1 Titan analysis chamber. The analysis area where the x-ray beam interacted with the object is beneath the denture. The chamber lid was closed for analysis. Left, different view where it is possible to see the X-ray fluorescence spectrometer S1 Titan beneath the analysis chamber. The trigger had to pressed during the analysis; the time corresponding to the acquisition time. Figure S7. Handheld Raman spectra of the celluloid dentures’ from NMD and NMAH, namely SSW19 (10 s), 2002.99.4796 (7 s), 2022.99.5818 (8 s), 2022.99.5287 (6 s), 92.2.0924 [10], MG.M-09686 dental blank (2.6 s) and JUSTI 21 (7 s). Figure S8. Infrared spectra of the celluloid dentures’ microsamples from NMD and NMAH. Figure S9. Photographs with a 65MP camera (top) and with a Dinolite USB digital microscope AM2111-0.3MP (bottom) showing the overall conservation condition of 2002.99.5780, showing the brown areas across the red celluloid and yellowed teeth with dark spots. Figure S10. Photographs with a 65MP camera (top) and with a Dinolite USB digital microscope AM2111-0.3MP (bottom) showing the conservation condition of 92.2.0924, namely the pitting effect at the celluloid gums. Figure S11. Handheld Raman spectra of the teeth of celluloid dentures SSW19 (2 s) and MG.M-09686 denture 1 (3.7 s). The tooth analyzed for each denture is identified with a circle. Figure S12. XRF spectrum of NMAH’s vulcanized rubber denture MG.291116.0046 in three different points, marked in the denture’s photograph. Figure S13. Infrared spectrum of a calcium stearate reference, for more details on this reference preparation and characterization please see Otero et al. (2014). Figure S14. Infrared spectra of NMD dental plate 2002.99.5496 (probably a Luxene dental plate from the Bakelite Corporation). Figure S15. Infrared spectra of NMD dental plate JUSTI 23 identified as PMMA. Bands at 1731 and 1150 cm−1 are saturated.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Neves, A., Friedel, R., Callapez, M.E. et al. Safeguarding our dentistry heritage: a study of the history and conservation of nineteenth–twentieth century dentures. Herit Sci 11, 142 (2023). https://doi.org/10.1186/s40494-023-00989-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-023-00989-2

Keywords

This article is cited by

-

History of dental biomaterials: biocompatibility, durability and still open challenges

Heritage Science (2023)