Abstract

The distribution of molar mass of historical and contemporary poly(vinyl chloride) objects was determined using size exclusion chromatography with multi-angle light scattering detection. The weight average molar mass was determined for a collection of 57 samples, ranging from 75 to 186 kg/mol with a median of 102 kg/mol. Rigid PVC objects were found to have a significantly lower weight average molar mass (Mw = 81 kg/mol) than plasticized ones (Mw = 102 kg/mol). Thin objects also exhibited significantly lower Mw than bulky objects. A substantial presence of aggregates was noted and characterized as an ‘aggregate ratio’ for the entire collection. Heating a solution of poly(vinyl chloride) in THF at 55 °C for 5 h proved successful in the dissociation of the aggregates and allowed for an accurate determination of molar mass. The uncertainty of the Mw determination was statistically evaluated and used to study the effects of accelerated degradation on Mw. No statistically significant changes in Mw were observed in samples artificially aged at 50 °C to 80 °C for up to 15 weeks, indicating that Mw does not decrease during degradation of a PVC heritage object and that accelerated degradation does not lead to polymer crosslinking.

Similar content being viewed by others

Introduction

Historical and contemporary poly(vinyl chloride) (PVC) objects are made of a polymer (PVC) and additives, used to adjust material stability and performance to the intended use of the item [1,2,3]. These are diverse groups of compounds, such as plasticizers [4, 5], fillers, pigments, heat stabilizers, antioxidants, and biocides. Although PVC is used in a wide variety of objects [6] (e.g. inflatables, sculptures, raincoats, toys and trinkets, tubing) and PVC objects represent significant parts of contemporary museum collections (a POPART collection survey found up to 13% of objects containing PVC [7,8,9,10]), there is a lack of knowledge about the range and distribution of PVC molar mass in such collections. PVC can also be found in important artworks and design pieces (Hervé Fischer’s Essuie-mains/Hygiène de l'art (1941) [11], Joseph Beuys’ Postkarten (1968–1974) [12], Tadeusz Kantor’s Umarła klasa (The Dead class, 1975) [13], Alberto Burri’s Rosso Plastica (1961) [14], Glen Kaufman’s The Knights (1976) [15], Quasar Khan’s Plafonnier (1968) [16], Dieter Roth’s Poemetrie (1967–68) [17], Ralph Borland’s Suited for Subversion (2002) [18], Paolo Lomazzi, Donato D'Urbino and Jonathan De Pas’s Blow Inflatable Armchair (1976) [19], etc.) The polymer is commonly synthesized by suspension or emulsion polymerization [2], which leads to the polymer having a broad molar mass distribution [20]. The molar mass distribution and average molar mass (Mn—number average, Mp—peak, Mw—weight average, Mz—z-average) of a given polymer have a tremendous effect on the mechanical and thermal properties of the polymer. A polymer with a high molar mass is characterized by a higher glass transition temperature (Tg) [21] and increased mechanical properties, such as impact resistance and tensile strength [22]. The Mw of certain polymers is believed to correlate with their mechanical [23, 24] properties (e.g. fibroin from silk [25]). Various polymer properties such as structural irregularities originating from allylic and tertiary chlorines (branching points) arise from the polymerization process and act as starting points of dehydrochlorination [1, 26,27,28,29], which the polymer is prone to. Dehydrochlorination is a thermal reaction that results in the formation of polyene sequences that cause yellowing [30,31,32,33,34].

The molar mass of PVC is routinely determined by size exclusion chromatography (SEC) with a differential refractive index detector (dRI) using conventional calibration with narrow molar mass standards (most commonly polystyrene (PS), polybutadiene (PBD), polyisoprene or poly(methyl methacrylate) (PMMA)) [35]. In conventional calibration, the logarithm of the molar mass is plotted against the elution volume. Narrow PVC standards are rare and difficult to obtain, therefore narrow PS standards are commonly used, and the calculated molar mass is reported as “relative to a narrow PS standard”. The obtained values are of limited accuracy because of the assumption that the analytes have the same conformation and hydrodynamic volume as the calibration standards and it relies on the stability of the elution time [35, 36]. For better accuracy, universal calibration with an online viscometer can be used. In such cases, the Mark-Houwink coefficients for the analyte and the standards in the eluent must be known, although the method is still limited due to frequent calibrations needed to correct for flow rate drift, temperature fluctuations, and column deterioration.

Accurate determination of molar mass is of great importance for investigating degradation-induced changes to the polymer chain. SEC with multi-angle light scattering detection (MALS) and differential refractive index detector (dRI) as a concentration detector is the most reliable technique for studying such changes [37]. SEC-MALS is an absolute technique for the determination of molar mass and the average root mean square radius (RMS) of the macromolecules in a solution that does not depend on the molecular conformation or non-ideal column interactions, as elution time or volume are not used in the molar mass calculations [35, 37, 38]. A laser beam irradiates a molecule and causes it to scatter the light at different angles. Based on the Zimm formalism, the Rayleigh-Debye-Gans light scattering model for a dilute polymer solution can be expressed by Eq. 1,

describes how the Mw and the RMS radius are measured from light scattering, where the intensity of the scattered light is expressed as the excess Rayleigh ratio (Rθ, cm−1) for each of the multiple angles around the molecule, c is the concentration of the polymer, K* is the optical constant proportional to (dn/dc)2, and A2 is the second virial coefficient. Plotting K* c/Rθ against c, the y-intercept is inversely proportional to the Mw and the slope is inversely proportional to the RMS radius.

According to the literature [39,40,41] PVC dissolved in THF tends to form high molar mass particles. This phenomenon is termed aggregation, multimerization or association [42]. Aggregates are clusters of single polymer chains that are entangled or clumped together through physical interactions and recognized by a narrow peak eluting before the main polymer fraction in the MALS detector. In the case of PVC (and also in poly(ethylene oxide) [43]) no dynamic equilibrium between aggregates and individual polymer chain exists, therefore dilution of a polymer solution does not lead to the aggregates’ dissociation [44]. In this work, aggregation refers to aggregates that show no concentration dependence and can be broken up by using heating or solvent modifiers, making them distinctly different from high-molar mass polymer fractions [35, 45]. In contrast, irreversible aggregates (as encountered in protein aggregation or denaturation) cannot be broken up using heating and exhibit a concentration dependence (increased aggregation with increasing concentration). PVC exhibits small amounts of aggregates in thermodynamically good solvents (THF, cyclohexanone, THF with < 40% allyl alcohol), while large amounts of aggregates [46] are present in thermodynamically bad solvents (γ-butyrolactone, anisole amyl acetate, dichlorobutane, mixtures of THF with > 40% allyl alcohol). In THF, the aggregates are usually present in amounts < 0.01% [46], so they are rarely observed in conventional SEC analysis with the dRI detector, but are easily detected by SEC-MALS due to intensive light scattering, and can lead to molar mass overestimation. Therefore, for accurate molar mass determination aggregates need to be dissociated into individual molecules.

In 1972, a study by Abdel-Alim and Hamielec [40] noticed the appearance of aggregates in a solution of PVC in THF with an apparent molar mass of 11–25-times that of a single molecule using SEC with a light-scattering detector. With a lower temperature of bulk polymerization, the amount of aggregates formed in the solution increased. A higher polymerization temperature was connected to the production of PVC with low syndiotacticity (measured by NMR) and low crystallinity. A 10-min treatment of the THF solution at 90 °C was proposed to disintegrate the aggregates into single strands [39]. In 2006, Coelho et al. [41] proposed using a 1-h ultrasonic treatment to break up the aggregates. Heating a THF solution above its boiling point would require specialised glassware and may lead to unwanted thermal degradation of the polymer, while using sonication could lead to shearing degradation. The process of dissolution of aggregates required optimisation and validation to make it appropriate for studying a large collection and investigating changes during degradation.

Thermal degradation of PVC proceeds by the elimination of hydrogen chloride and leads to the formation of polyene sequences [26, 47, 48]. The mechanism of polymer degradation and its effects can be better understood by investigating changes in the molar mass of PVC samples before and after accelerated degradation, which requires accurate molar mass determination with SEC-MALS-dRI. The molar mass of the polymer was shown to play a smaller but contributing role in the discolouration of PVC objects [47].

The first objective of our research was to establish a protocol to dissociate the aggregates that would work for a wide variety of PVC samples. The effect of heating and sonication times were compared and statistically evaluated to determine the uncertainty of the method, which proved to be critical in interpreting possible changes in molar mass due to the thermal degradation of the samples. The second goal was to gain a fundamental insight into heritage PVC collections and their degradation by the characterisation of 57 PVC objects with unknown histories, different compositions, item types, and degradation states and evaluating these results in terms of grouping by historical/contemporary, with/without plasticizer, thin/bulk, and with/without filler. Lastly, we aimed to determine the effect of the accelerated degradation on the molar mass of the polymer.

Experimental

Materials

Inhibitor-free HPLC-grade tetrahydrofuran (THF) was purchased from Chempur (Poland). Syringe filters (PTFE, 0.45 um) used for sample filtration were supplied by Biospace (Poland). The analysis was carried out on part of a collection of PVC objects described previously [49]. The data obtained as part of the study is available as Additional file 1.

Reference collection of historical and contemporary PVC objects

In this study, more than 55 PVC samples from the reference collection available at the Heritage Science Lab Ljubljana were analysed to gain insight into the distribution of molar mass. The objects are up to 30 years old and have an unknown production and storage history. They are inflatable objects, flat sheets, figurines, raincoats and rain boots with different material compositions in terms of plasticizer and filler. Since they cover a wide range of compositions, they could be considered representative of heritage collections whose distribution of molar mass is largely unknown. Some of the historical transparent sheet protectors exhibited discolouration ranging from slight to intense yellow. One sample (P238A) was very brittle and had cracks. A more detailed description of the reference collection is available in the Additional file 1: Table S1.

Accelerated degradation

Selected sacrificial PVC objects were subjected to accelerated degradation at the following conditions: 50 °C and 30% relative humidity (RH), 50 °C and 80% RH, 70 °C and 30% RH, 70 °C and 80% RH in Vötsch climate chambers VC 0018 and at 80 °C with no humidity control (estimated < 7% RH) in Venticell 55 air dryer with air circulation.

Optimization of sample preparation for SEC-MALS analysis

Approximately 4 mg of a sample were accurately weighed and dissolved in 4 mL of THF to form a solution with a concentration of 1 mg/mL. 1 mL of the solution was then filtered through 0.45 μm PTFE filter into an HPLC vial and analysed with SEC-MALS-dRI. The vial with the remaining solution was placed in an oil bath heated to 55 °C or into an open ultrasonic bath Bandelin Sonorex (35 kHz) for different periods of time.

Size exclusion chromatography and molar mass calculation

SEC analyses were performed using Waters Breeze HPLC system consisting of 1515 isocratic pump, 717 + autosampler, columns oven, multi-angle light scattering (Dawn Heleos, Wyatt Technology) and differential refractive index detectors (t-rEX, Wyatt Technology), both working at 658 nm wavelength. Tetrahydrofuran was used as the mobile phase at 1 mL/min. PVC solutions were injected (100 µL volume) into two mixed-bed DVB Jordi columns (25 × 1 cm, separation range 100–10,000,000 g/mol), equipped with a Jordi precolumn. The columns and dRI detector’s cell were maintained at 30 °C. The collected data were processed in Astra 6.1.1.17 software (Wyatt Technology). For the calculation of molar mass from Rayleigh equation, a dn/dc value equal to 0.100 mL/g was used. Light scattering data were fitted according to Zimm’s formalism (Eq. 1).

Colour difference

The colour of the original PVC1 sample and PVC1 after accelerated degradation was measured using a ColorQuest XE instrument (HunterLab) equipped with a standard illuminant C and expressed in the CIELAB colour space. Each measurement was performed in triplicate and averaged. The yellowing index (Δb*) was determined on the basis of *b parameter, which ranges from –120 (blue) to + 120 (yellow). The colour difference ΔE00 was calculated according to the CIEDE2000 definition [50].

Results and discussion

The goal of this research was to optimize sample preparation for accurate and precise determination of the molar mass of PVC objects using SEC-MALS-dRI. SEC columns for organic applications are usually packed with styrene–divinylbenzene gels of specific pore sizes that enable the analysis of polymers in a selected molar mass range without them interacting with the stationary phase. In SEC-MALS-dRI, the molecules are first separated according to their hydrodynamic size and then an online light scattering detector determines their molar mass according to the Zimm formalism (Eq. 1) as they elute. During the initial analysis of certain PVC samples, intense scattering, characteristic for the presence of aggregates was observed. The polymer strands, which are part of the aggregates, are excluded from the main peak and thus not evaluated, which can lead to the inaccurate characterization of the sample. Therefore, the aggregates need to be broken up before analysis. After the procedure was optimised, a larger group of diverse and real samples was analysed, which can give an insight into the distribution and trends expected in heritage collections. The presented research work uses SEC-MALS-dRI to evaluate the molar mass of PVC in various objects, statistically examines where the aggregates are likely to be found and investigate the effect of thermal degradation on the molar mass of the polymer.

Optimisation of sample preparation for accurate determination of molar mass

Aggregates often occur in polymers with high molar mass, polymers with crystalline regions and branched polymers [35, 36]. Intense scattering, characteristic for aggregates, was observed in several PVC objects from the investigated collection (Fig. 1). They were found to have Mw of 1 000–3 000 kg/mol with a hydrodynamic radius of 35 nm, i.e., they consisted of 10–30 individual polymer strands, which made them very compact. It is recommended to use long periods of dissolution or elevated temperature to break them up.

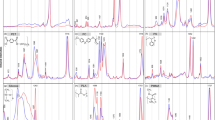

The intensity of aggregates in the solution of sample PVC2. The curved lines correspond to the intensity of the light scattering signal, while the straight lines present the molar mass of the fraction eluting at the time. The single polymer strands elute as the fraction with an apex at 18.5 min, and the aggregates elute as a fraction with an apex at 15.5 min. The relative signal for aggregates decreases with longer heating times and eventually becomes a shoulder of the main fraction. Trace amounts of aggregates are still visible with the MALS detector, which do not contribute to a miscalculated Mw, because the signal on the dRI detector is negligible

In 1967, Kratochvíl et al. [46] have investigated the aggregates formed in solutions of PVC with thermodynamically good and bad solvents by light-scattering and sedimentation analysis. They have noted that heating a PVC solution prepared in a good solvent (2 h at 55 °C for THF and 1 h at 80 °C for cyclohexanone) reduced the light scattering (LS) intensity by 10–50% but have not evaluated the procedure for dissociating the aggregates more thoroughly. As indicated by the literature reviewed, researchers have mainly used short heating times to temperatures above the boiling point of THF [39, 40] or sonication [41, 51]. The results of such approaches need to be carefully examined, especially when studying the changes to molar mass caused by degradation at low temperatures (up to 80 °C). Many previous studies were performed on a limited number of samples of similar origin (purpose made samples) and should be tested on a broader group of PVC objects. Initially, 1-h sonication was taken as a starting point from Coelho et al. [41], which proved to be insufficient for the analysis of the samples in our collection of PVC items. Mechanical agitation [35] can cause shear degradation and should be used with caution. Sonication was also accompanied by an increase of temperature. When the ultrasonic bath was used without a lid, the temperature reached 45 °C for 1 to 12 h of sonication. Therefore, the effects of heating and sonication times on aggregate dissolution were systematically studied.

Two sacrificial PVC objects were selected from the reference collection as model samples for establishing an appropriate procedure for dissolving the aggregates. PVC2 is a thin contemporary transparent sheet that exhibited significant MALS signals in solution due to the presence of aggregates, while PVCM is an inflatable contemporary beach ball that exhibited minor MALS signals in solution due to the presence of aggregates. The whole object list and descriptions are available in Additional file 1: Table S1. Three independent replicates for each heating and sonication time were prepared for two PVC objects. The following heating and sonication times were tested: 1, 3, 5, 8, 12 h (Fig. 1).

The determined Mw of the sample PVC2 after the preparation steps are given in Fig. 2. The apparent Mw decreased with longer times of heating and sonication. A significant decrease in Mw was observed for the heating times of 1 and 3 h (ANOVA results in the Additional file 1: Table S2), but no significant differences are observed after 5, 8 or 12 h. A plateau was observed after 5 h of heating and after 8 h of sonication (Fig. 2). Based on these results, heating the solutions for 5 h at 55 °C was chosen as the general procedure to dissociate the aggregates. Figure 1 shows that small amounts of aggregates can be detected with MALS even after the proposed 5 h of heating, which did not affect the correct determination of Mw because the dRI signal for this fraction was negligible and thus it did not contribute significantly to Mw. Shorter times of treatment are preferable to avoid the risk of degradation and for practical reasons. Long sonication times can be particularly problematic, as they can lead to shear degradation of the polymer [35]. No degradation was observed at any of the tested heating or sonication times tested. The uncertainty of the method was determined as the pooled standard deviation of the measurements at heating times 5, 8 and 12 h, which was ± 2250 g/mol (2.25% coefficient of variation). Sample PVCM, which initially displayed fewer aggregates, behaved similarly. The results confirmed that heating at 55 °C for 5 h successfully broke up the aggregates (Additional file 1: Fig. S1).

The proposed procedure to dissociate aggregates was proved to be successful even for samples with larger amounts of aggregates. For example, in the solution of object P124 (a rain boot), enormous amounts of aggregates are present initially, which are completely broken up after heating (Fig. 3 A). The molar mass plot (diagonal data set overlayed on chromatograms) shows the possible mischaracterisation if the aggregates were not broken up. In Fig. 3B a conformation plot is presented, referring to the relation between the root mean radius of a polymer and the corresponding molar mass. This plot is of practical use when describing macromolecular architecture and investigating possible branching. The RMS vs molar mass plot initially exhibits a lower and a noticeable upwards curvature at the low molar mass region. With increased molar mass, the RMS does not change linearly, suggesting a more compact structure of a polymer molecule. After the thermal treatment (5 h at 55 °C) the plot is clearly linear, and the slope value is higher. It served as an additional proof that the aggregates have been broken up during heating. It is worth noting that the RMS curve indicates a slope value < 0.5 even after heating the PVC solution, which is characteristic of branched polymers [35]. This was observed for the whole analysed collection as well as for the samples exposed to accelerated degradation. Therefore, it appears that the samples exhibit some degree of branching from the very beginning. It was not possible to detect further evolution of branching or crosslinking with polymer state of degradation.

A An elugram of P124 presented as the detected molar mass vs. elution volume before (black line) and after (red line) heating for 5 h at 55 °C. B The RMS conformation plot before (black line) and after (red line) heating for 5 h at 55 °C. Before the heating, fractions with a high molar mass and a uniform RMS can be observed. After heating, the aggregates are broken up to single chains, which exhibit a linear relation of RMS vs. molar mass

Analysis of aggregates in the PVC reference collection

To provide a better description of the frequency and extent of the aggregates in PVC, an “aggregate ratio” was determined. The aggregate ratio was determined as the ratio of the height of the aggregate fraction and the height of the main polymer fraction of the LS detector for solutions that did not undergo any heating or ultrasound treatment. The concentration dependence of the aggregate ratio was also investigated (Additional file 1: Fig. S2). It was found that the absolute signal on the MALS detector for aggregates increases with increasing the PVC concentration, but the aggregate ratio remains constant with concentration. As such they are assumed to be formed during the dissolution process. The observed concentration dependence could be due to either dilution of both single chains and aggregates or a dynamic, reversible process of aggregation. The solutions remained stable for 1 week after heating, and aggregates no longer appeared. It can be concluded that the aggregates are not in dynamic equilibrium with the individual polymer chains and are formed by the dissolution process.

The aggregate ratio was calculated for 57 PVC objects in the collection before heating the solutions for 5 h at 55 °C and rounded to one decimal place (Additional file 1: Fig. S3). Aggregates were detected in all PVC objects studied, and the ratio > 0.2, which can be considered disruptive of an accurate Mw, was present in 63% of the collection. 9% of the collection had an aggregate ratio ≥ 1. After the proposed treatment, the aggregate ratio of all the samples was < 0.1, which gives accurate results for the Mw. An example of an elugram of a sample with substantial amounts of aggregates with the determined Mw before and after heating is presented in Fig. 3A.

The investigated objects were categorized according to 4 different descriptions (Fig. 4), such as whether they were contemporary (10; purchased in the last 5 years) or historical (47; older than 20 years), whether they had filler (22; calcium or titanium based) or not (35), whether the objects contained plasticizer (49) or not (8), and whether the objects were thin (34; < 0.5 mm) or bulky (23; > 2 mm). A Wilcoxon-Mann–Whitney test at the 0.05 significance level was used to compare the distribution of the aggregate ratio of the non-heated solutions according to the categories. PVC objects with plasticizers were found to have a significantly different aggregate ratio distribution from rigid PVC (p = 0.05, Fig. 4). The other categories showed no significant difference in the aggregate ratio.

A boxplot for the distribution of the aggregate ratio in the 57 PVC objects in the investigated collection. On the left the distribution of the whole collection is presented, while on the right of it, the distributions of the aggregate ratio of objects according to the categories are presented. Dashed lines separate different categories by which the objects were compared

Figure 5 presents the lack of correlation between the Mw and the aggregate ratio. Therefore, it can be assumed that short and long chain molecules are equally likely to form aggregates. As mentioned in the Introduction section, tacticity (regulated by the temperature of polymerization) is considered as the main factor contributing to a higher or lower abundance of high molar mass clusters even in dilute solutions of PVC. Judging by the wide range of the aggregate ratio determined in the PVC objects from our collection, different polymerization processes were likely used. This, again, highlights the need for aggregate removal from PVC in solutions, as the parameters of the polymerization process are unknown for the majority of historical and most of contemporary PVC objects.

Molar mass of historical and contemporary PVC objects

The determined weight average molar mass of 57 PVC objects ranged from 75 to 186 kg/mol with a median of 102 kg/mol and a mean of 105 kg/mol (Additional file 1: Fig. S4). The results are presented in Additional file 1: Table S1 and Fig. 6. Pepperl [20, 52] has reported the Mw ranges of PVC according to the polymerization technology by using narrow PS standards and the Mark-Houwink coefficients for PVC. Suspension polymerization produced PVC with a Mw in the range of 38–179 kg/mol, emulsion polymerization produced PVC with the Mw in the range of 62–131 kg/mol and bulk polymerization produced the Mw in the range of 53–78 kg/mol. While the origin and the polymerization technology of the PVC objects in the studied collection are unknown, we can conclude that most of the objects were produced using suspension or emulsion polymerization.

A boxplot for the distribution of the Mw for the 57 PVC objects in the investigated collection. On the left the Mw of the whole collection is presented, while on the right of it, the distributions of the Mw of objects according to the categories are presented. Dashed lines separate different categories by which the objects were compared

The investigated objects’ characteristics were categorized according to 4 different descriptions, described in the previous section. A preliminary look at the histogram and the Shapiro–Wilk normality test demonstrated that the data of Mw does not follow a normal distribution at the 0.05 significance level (p = 0.00001). Therefore, the non-parametric Wilcoxon–Mann–Whitney tests were carried out to compare the distribution of the Mw of the samples according to the following categories: Historical/Contemporary, Filler/No Filler, Soft (Containing plasticizer)/Rigid (no plasticizer) and Thin/Bulk at the 0.05 significance level. The results of the test (Fig. 6) show there are no significant differences in the distribution of Mw of samples according to the category historical/contemporary and at the filler/no filler category. On the other hand, rigid PVC objects (median Mw = 81 kg/mol) were found to have a significantly different Mw from PVC objects with plasticizers (median Mw = 102 kg/mol; p = 0.0005). A significant difference in Mw was observed when comparing thin objects (median Mw = 93 kg/mol) with bulk objects (median Mw = 105 kg/mol; p = 0.004). Low molar mass PVC resins are used in the manufacturing of rigid objects due to the lower required temperature and less danger of shear degradation during processing. High molar mass PVC resins have a higher viscosity, so they are used in combination with plasticizers to produce soft PVC [1]. Compared to the PVC produced in the 1980s, with a number average molar mass (Mn) in the range of 35–80 kg/mol, the commercial polymers produced today were reported in the range of 20–70 kg/mol [1]. In this study, PVC with a Mn of 45–120 kg/mol was observed, although a direct comparison of values is not possible due to the different principles of determination of the Mw. This kind of preference for lower Mw PVC resins might also explain the observed differences in thin PVC sheets, which are made with calendering [2].

Another characteristic of a polymer is its polydispersity index (PDI), which describes the non-uniform mass distribution of polymer molecules. It is calculated as PDI = Mw /Mn, so a uniform polymer has a PDI = 1, while values > 1 are characteristic of non-uniform polymers. The dispersity of PVC objects in this study ranged from 1.4 to 1.8 with a mean and a median of 1.6 (Additional file 1: Fig. S5). A study reported a linear increase of PDI with increasing Mw [20, 52], while the results of our study show no such correlation (Additional file 1: Fig. S6). Their observations were likely based on the combination of specific technological processes and processing conditions, but the relation is not expected to hold for a general mixed collection of PVC objects.

Changes in Mw during degradation

The accuracy of an analytical method is crucial in interpreting degradation-induced changes to the molar mass. Optimization and repeatability tests showed that the method’s uncertainty was ± 2250 g/mol (2.25% coefficient of variation). Since the PVC objects in the collection and the pieces exposed to accelerated degradation were available in limited amounts, the samples were analysed once. The two standard deviation rule was selected as the significance criteria when comparing the Mw of an original object and a piece of it exposed to accelerated degradation (± 4500 g/mol). The results are presented in Fig. 7. The conditions and time of accelerated degradation are presented in the legend of Fig. 7. A Δb* = 26 and ΔE00 = 25 were determined for PVC1 after 10 weeks of accelerated degradation at 80 °C. In 2001, a ΔE00 value of 1.5 has been proposed as a ‘perceptible change’ and 10 perceptible changes have ben used as defining an object’s lifetime [53]. Additionally, a Δb* = 15 was recently proposed as the lifetime of transparent colourless PVC objects [47]. Therefore, looking at the PVC1 object from a perspective of colour change in the heritage context it could be considered already past its lifetime, but no significant changes in Mw could be determined.

The effect of accelerated degradation on the Mw of a PVC object. The difference in Mw for an object after and before accelerated degradation is plotted and compared against two standard deviations (± 4500 g/mol). The conditions and time of accelerated degradation are presented in the legend, with the time of degradation expressed in weeks (w)

There are few reports investigating changes in Mw of PVC objects that are not focused on a specific case study. Kratochvíl et al. [46] have exposed a solution with no initial aggregates to high oxygen pressure and heating to 50–80 °C and observed that a high content of high molar mass fractions was formed during degradation (using SEC-MALS). These high-molar mass fractions were stable at elevated temperatures. High oxygen pressure and heating led to oxidative degradation by crosslinking of the polymer. Covalent bonds were formed during the oxidative degradation, which makes these high molar mass entities different from the reversible aggregates. Crosslinking in PVC also occurred when heating a solution at 120 °C for 3 h [54], as determined using calibration with narrow PS standards and Mark-Houwink parameters for PVC. An accelerated weathering test carried out at 50 °C for 80 days with included UV degradation revealed a simultaneous decrease of Mw and crosslinking of a polymer, based on SEC performed with calibration with narrow PS standards [55]. PVC was also exposed to a weathering test at 100 °C with light irradiation and cyclic spraying of water for 125 days and no changes to Mn were observed when using narrow PS standards for calibration [56]. These kinds of studies rarely report the accuracy of their determined Mw, which is critical in interpreting significant changes. Crosslinked products were not present in the objects included in this study, proving that thermal degradation in the solid state of an object with temperatures up to 80 °C led to no crosslinking and is suitable for accelerated degradation experiments. All of the studied objects were made of slightly branched PVC, and no changes to the branching was observed during degradation (Additional file 1: Fig. S7).

Conclusions

The presence of high molar mass fractions on the MALS detector was studied and the fractions were identified as reversible aggregates. The presence of aggregates in PVC solutions was investigated for a collection of 57 objects by establishing an aggregate ratio, and the characteristic properties of the aggregation process were explored. In this work, a sample preparation procedure based on thermal pre-treatment prior to analysis is proposed for the accurate determination of the molar mass of historical PVC samples using SEC-MALS-dRI. The effect of heating time on the molar mass was investigated and statistically evaluated to determine the uncertainty of the method. It was found that heating the solution to 55 °C for 5 h sufficiently breaks up the aggregates for all the PVC objects studied. The weight average molar mass determined for a collection of 57 PVC samples ranged from 75 to 186 kg/mol with a median of 102 kg/mol. The approach presented here may also be useful for the dissociation of aggregates in other polymer–solvent systems. In addition, the methodology developed, in conjunction with a reliable and accurate SEC-MALS analysis, allowed us to study the differences in molar mass due to accelerated degradation. No significant changes in Mw were observed during the accelerated degradation of samples exposed to 50–80 °C for up to 10 weeks. An interesting observation can be made based on the sample exposed to 80 °C for 10 weeks, that no significant change in the Mw occured during the lifetime of a heritage object i.e., when significant yellowing was observed. This is the first reported characterization of a wide variety of PVC objects and provides insight into the so far unknown distribution of Mw in heritage collections. Statistical analysis of the distribution of the determined Mw showed that rigid PVC has a significantly lower Mw than plasticized PVC, which was also true for thin objects compared to bulky objects. In contrast, the distinction between contemporary and historical, and the presence of fillers was not significant. The proposed methodology and uncertainty guidelines could be transferrable to investigating changes to molar mass due to UV degradation of PVC (crosslinking) and the degradation of other polymer types.

In future research focused on the thermal degradation of PVC objects, the degradation of the polymer fraction could be studied with more sensitive and specific approaches, e.g., by focusing on the gaseous emissions of HCl and the formation of polyenes. Future research work will also focus on the changes of mechanical properties of the material, where the stability of Mw will be critical for constructing a suitable model.

Availability of data and materials

All data generated or analysed during this study are included in this published article and its supplementary information file.

Abbreviations

- dRI:

-

Differential refractive index detector

- LS:

-

Light scattering

- MALS:

-

Multi-angle light scattering

- Mn :

-

Number average molar mass

- Mw :

-

Weight average molar mass

- Mz :

-

Z-average molar mass

- PS:

-

Polystyrene

- PVC:

-

Poly(vinyl chloride)

- SEC:

-

Size-exclusion chromatography

- RMS:

-

Root mean square radius

References

Wypych G. PVC degradation and stabilization. 4th ed. Scarborough: ChemTec Publishing; 2020. https://doi.org/10.1016/C2019-0-00335-4.

Patrick S. Practical Guide to polyvinyl chloride. 1st ed. Shawbury: Rapra Technology; 2005.

Schiller M. PVC additives: performance, chemistry developments, and sustainability. 2nd ed. Cincinnati: Hanser Publications; 2022.

King R, Grau-Bové J, Curran K. Plasticiser loss in heritage collections: its prevalence, cause, effect, and methods for analysis. Herit Sci. 2020;8:123. https://doi.org/10.1186/s40494-020-00466-0.

Apchain E, Royaux A, Fichet O, Cantin S. A comparison between TGA, SEM-EDX and Raman spectroscopy to assess PVC plasticizer loss. J Cult Herit. 2022;57:79–87. https://doi.org/10.1016/j.culher.2022.07.008.

Mijangos C, Calafel I, Santamaría A. Poly(vinyl chloride), a historical polymer still evolving. Polymer (Guildf). 2023;266:125610. https://doi.org/10.1016/J.POLYMER.2022.125610.

POPART (Preservation Of Plastic ARTefacts in museum collections), Collection Survey, What is the condition of the collection?, http://popart-highlights.mnhn.fr/index.html. Accessed 17 Sep 2021.

Boyden MN, Kleist EM, Asztalos CK, Korter TM. Determination of the polymer composition of mid-twentieth century purses by Raman spectroscopy. Herit Sci. 2022;10:1–10. https://doi.org/10.1186/S40494-022-00743-0/TABLES/4.

Bell J, Nel P, Stuart B. Non-invasive identification of polymers in cultural heritage collections: evaluation, optimisation and application of portable FTIR (ATR and external reflectance) spectroscopy to three-dimensional polymer-based objects. Herit Sci. 2019;7:95. https://doi.org/10.1186/s40494-019-0336-0.

Mitchell G, France F, Nordon A, Tang PL, Gibson LT. Assessment of historical polymers using attenuated total reflectance-Fourier transform infra-red spectroscopy with principal component analysis. Herit Sci. 2013;1:1–10. https://doi.org/10.1186/2050-7445-1-28.

Centre Pompidou, Hervé Fischer’s Essuie-mains/Hygiène de l’art, (1941). https://www.centrepompidou.fr/en/ressources/oeuvre/c7rAeK.

MoMA, Josep Beuys’ Postkarten (1968–1974), (1968). https://www.moma.org/collection/works/99768.

Cricoteca, Tadeusz Kantor’s Umarła klasa (The Dead class), (1975). https://www.cricoteka.pl/pl/.

Guggenheim, Alberto Burri’s Rosso Plastica, (1961). https://www.guggenheim.org/audio/track/alberto-burri-rosso-plastica-m-2-red-plastic-m-2-1962.

Smithsonian American Art Museum, Glen Kaufman’s The Knights, (1976). https://americanart.si.edu/artwork/knights-33362.

Centre Pompidou, Quasar Khan’s Plafonnier, (1968). https://www.centrepompidou.fr/en/ressources/oeuvre/cpnRnkr.

Getty Conservation Institute, Dieter Roth’s Poemetrie, (1968). https://primo.getty.edu/permalink/f/19q6gmb/GETTY_ALMA21131704350001551.

MoMA, Ralph Borland’s Suited for Subversion, (2002). https://www.moma.org/collection/works/94361.

Centre Pompidou, Paolo Lomazzi, Donato D’Urbino and Jonathan De Pas’s Blow Inflatable Armchair, (1976). https://www.centrepompidou.fr/en/ressources/oeuvre/cpbXX6G.

Pepperl G. Molecular weight distribution of commercial PVC. J Vinyl Addit Technol. 2000;6:88–92. https://doi.org/10.1002/vnl.10229.

O’Driscoll K, Sanayei RA. Chain-length dependence of the glass transition temperature. Macromolecules. 1991;24:4479–80. https://doi.org/10.1021/MA00015A038/ASSET/MA00015A038.FP.PNG_V03.

Nunes RW, Martin JR, Johnson JF. Influence of molecular weight and molecular weight distribution on mechanical properties of polymers. Polym Eng Sci. 1982;22:205–28. https://doi.org/10.1002/PEN.760220402.

Sugimoto M, Hida H, Taniguchi T, Koyama K, Aoki Y. Rheological properties of poly(vinyl chloride)/plasticizer systems - Relation between sol-gel transition and elongational viscosity. Rheol Acta. 2007;46:957–64. https://doi.org/10.1007/S00397-007-0178-7/FIGURES/13.

Ward IM, Sweeney J. Mechanical properties of solid polymers. 3rd ed. Hoboken: Wiley; 2012. https://doi.org/10.1002/9781119967125.

N. Luxford. Reducing the Risk of open display optimising the preventive conservation of historic Silks, University of Southampton, 2009.

Starnes WH. Structural and mechanistic aspects of the thermal degradation of poly(vinyl chloride). Prog Polym Sci. 2002;27:2133–70. https://doi.org/10.1016/S0079-6700(02)00063-1.

Starnes WH, Ge X. Mechanism of autocatalysis in the thermal dehydrochlorination of poly(vinyl chloride). Macromolecules. 2004;37:352–9. https://doi.org/10.1021/ma0352835.

Starnes WH, Chung H, Wojciechowski BJ, Skillicorn DE, Benedikt GM, Auxiliary mechanism for transfer to monomer during vinyl chloride polymerization. 1996; pp. 3–18. https://doi.org/10.1021/ba-1996-0249.ch001.

Al-Mosawi AI. A novel evaluation method for dehydrochlorination of plasticized Poly(vinyl chloride) containing heavy metal-free thermal stabilizing synergistic agent. Polym Adv Technol. 2021;32:3278–86. https://doi.org/10.1002/PAT.5339.

Voyiatzis GA, Andrikopoulos KS, Papatheodorou GN, Kamitsos EI, Chryssikos GD, Kapoutsis JA, Anastasiadis SH, Fytas G. Polarized resonance Raman and FTIR reflectance spectroscopic investigation of the molecular orientation in industrial poly(vinyl chloride) specimens. Macromolecules. 2000;33:5613–23. https://doi.org/10.1021/ma991772m.

Lemaire J, Siampiringue N, Chaigneau R, Delprat P, Parmeland G, Dabin P, Spriet C. Towards the prediction of pinking of PVC profiles in mild climatic conditions. J Vinyl Addit Technol. 2000;6:69–79. https://doi.org/10.1002/vnl.10227.

Hollande S, Laurent JL. Study of discolouring change in PVC, plasticizer and plasticized PVC films. Polym Degrad Stab. 1997;55:141–5. https://doi.org/10.1016/S0141-3910(96)00165-6.

Royaux A, Apchain E, Fabre-Francke I, Balcar N, Barabant G, Bollard C, Lavédrine B, Fichet O, Cantin S. Conservation of plasticized PVC artifacts in museums: influence of wrapping materials. J Cult Herit. 2020. https://doi.org/10.1016/j.culher.2020.07.002.

Royaux A, Fabre-Francke I, Balcar N, Barabant G, Bollard C, Lavédrine B, Cantin S. Aging of plasticized polyvinyl chloride in heritage collections: the impact of conditioning and cleaning treatments. Polym Degrad Stab. 2017;137:109–21. https://doi.org/10.1016/j.polymdegradstab.2017.01.011.

Podzimek S. Light scattering, size exclusion chromatography, and asymmetric flow field flow fractionation: powerful tools for the characterization of polymers, proteins, and nanoparticles. Hoboken: Wiley; 2010.

Podzimek S. Truths and myths about the determination of molar mass distribution of synthetic and natural polymers by size exclusion chromatography. J Appl Polym Sci. 2014. https://doi.org/10.1002/app.40111.

Wyatt PJ. Light scattering and the absolute characterization of macromolecules. Anal Chim Acta. 1993;272:1–40. https://doi.org/10.1016/0003-2670(93)80373-S.

Hsieh AH, Corti DS, Franses EI. Rayleigh and Rayleigh-Debye-Gans light scattering intensities and spetroturbidimetry of dispersions of unilamellar vesicles and multilamellar liposomes. J Colloid Interface Sci. 2020;578:471–83. https://doi.org/10.1016/J.JCIS.2020.05.085.

Salovey R, Gebauer RC. Molecular aggregation in poly(vinyl chloride). J Appl Polym Sci. 1973;17:2811–22. https://doi.org/10.1002/APP.1973.070170918.

Abdel-Alim AH, Hamielec AE. Molecular aggregation in poly(vinyl chloride). A novel analytical technique. J Appl Polym Sci. 1972;16:1093–101. https://doi.org/10.1002/APP.1972.070160504.

Coelho JFJ, Gonçalves PMFO, Miranda D, Gil MH. Characterization of suspension poly(vinyl chloride) resins and narrow polystyrene standards by size exclusion chromatography with multiple detectors: online right angle laser-light scattering and differential viscometric detectors. Eur Polym J. 2006;42:751–63. https://doi.org/10.1016/j.eurpolymj.2005.09.023.

Huglin MB. Light scattering from polymer solutions. London, New York: Academic Press; 1972.

Khan MS. Aggregate formation in poly(ethylene oxide) solutions. J Appl Polym Sci. 2006;102:2578–83. https://doi.org/10.1002/app.24687.

Rudin A, Benschop-Hendrychova I. Measurement of molecular weight of poly(vinyl chloride). J Appl Polym Sci. 1971;15:2881–904. https://doi.org/10.1002/app.1971.070151201.

Sitar S, Aseyev V, Žagar E, Kogej K. Chain dynamics and intermolecular association in dilute aqueous solutions of isotactic and atactic Poly(Methacrylic acid): Effect of NaCl concentration. Polymer (Guildf). 2019;174:1–10. https://doi.org/10.1016/J.POLYMER.2019.04.044.

Kratochvíl P, Petrus V, Munk P, Bohdanecký M, Šolc K. A physicochemical study of poly(vinyl chloride) in solution. J Polym Sci Part C Polym Symp. 1967;16:1257–67. https://doi.org/10.1002/POLC.5070160305.

Rijavec T, Strlič M, KraljCigić I. Damage function for poly(vinyl chloride) in heritage collections. Polym Degrad Stab. 2023;211:110329. https://doi.org/10.1016/j.polymdegradstab.2023.110329.

Hjertberg T, Martinsson E, Sӧrvik E. Influence of the dehydrochlorination rate on the degradation mechanism of poly(vinyl chloride). Macromolecules. 1988;21:603–9. https://doi.org/10.1021/ma00181a010.

Rijavec T, Ribar D, Markelj J, Strlič M, Kralj Cigić I. Machine learning-assisted non-destructive plasticizer identification and quantification in historical PVC objects based on IR spectroscopy. Sci Rep. 2022;12:1–11. https://doi.org/10.1038/s41598-022-08862-1.

Luo MR, Cui G, Rigg B. The development of the CIE 2000 colour-difference formula: CIEDE2000. Color Res Appl. 2001;26:340–50. https://doi.org/10.1002/col.1049.

Kunaver M, Anžlovar A, Žagar E. The fast and effective isolation of nanocellulose from selected cellulosic feedstocks. Carbohydr Polym. 2016;148:251–8. https://doi.org/10.1016/J.CARBPOL.2016.04.076.

Pepperl G. Molecular weight distribution of commercial emulsion grade PVC. J Vinyl Addit Technol. 2002;8:209–13. https://doi.org/10.1002/VNL.10364.

Ashley-Smith J, Derbyshire A, Pretzel B. The continuing development of a practical lighting policy for works of art on paper and other object types at the Victoria and Albert Museum, 13th Trienn. Meet. Rio Janeiro Prepr. 2002;1: 3–8.

Abbås KB, Sörvik EM. On the thermal degradation of poly(vinyl chloride). IV. Initiation sites of dehydrochlorination. J Appl Polym Sci. 1976;20:2395–406. https://doi.org/10.1002/app.1976.070200909.

Yang TC, Noguchi T, Isshiki M, Wu JH. Effect of titanium dioxide on chemical and molecular changes in PVC sidings during QUV accelerated weathering. Polym Degrad Stab. 2014;104:33–9. https://doi.org/10.1016/j.polymdegradstab.2014.03.023.

Ito M, Nagai K. Analysis of degradation mechanism of plasticized PVC under artificial aging conditions. Polym Degrad Stab. 2007;92:260–70. https://doi.org/10.1016/j.polymdegradstab.2006.11.003.

Acknowledgements

The authors thank Dr Ema Žagar from the Chemical Institute for the help and discussions about the aggregates. The authors thank Marek Bucki from the Jagiellonian University for the colour measurements of degraded PVC.

Funding

The authors acknowledge financial support through the PVCARE project (Slovenian Research Agency project no. N1-0241 and Polish National Science Centre (NCN) project OPUS-LAP 20, No. 2020/39/I/HS2/00911). T.R. and I.K.C. acknowledge the Research Core Funding P1-0153 (Slovenian Research Agency). Further acknowledged are the E-RIHS.si research infrastructure funding for analytical equipment at University of Ljubljana used in this project, (I0-E012, I0-0022), all Slovenian Research Agency. T.R. acknowledges support through the Erasmus+ KA1 131 project.

Author information

Authors and Affiliations

Contributions

TR Conceptualization, Writing—original draft preparation, investigation (optimisation and SEC analysis of the samples), Formal analysis, data curation, statistical interpretation; DP Investigation (optimisation and SEC analysis of the samples), conceptualization, formal analysis, data curation, writing—review and editing; KK, MS Conceptualization, writing—review and editing, project administration, funding acquisition; IKC Conceptualization, writing—review and editing, supervision. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Table S1.

The description of the reference collection and the results of the molar mass determination before and after aggregates’ dissociation. Table S2. The results of ANOVA tests for optimising the heating time. Figure S1. The effect of heating (55 °C) and sonication time on the determined MW in PVCM. Figure S2. The concentration dependence of the aggregate ratio. Part A depicts the intensity of the MALS signal when relative intensities are compared, part B depicts the absolute signals. Figure S3. A histogram of the aggregate ratio in the collection of 57 PVC objects. Figure S4. A histogram of the determined Mw in the collection of 57 PVC objects. Figure S5. A histogram of the dispersity in the collection of 57 PVC objects. Figure S6. Dispersity of PVC objects vs. their Mw. Figure S7. The RMS vs. Molar mass of P119 after the dissociation of aggregates to observe branching.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Rijavec, T., Pawcenis, D., Kruczała, K. et al. The significance of sample preparation of historical and contemporary poly(vinyl chloride) objects to investigate the distribution and changes of molar mass by SEC-MALS-dRI. Herit Sci 11, 155 (2023). https://doi.org/10.1186/s40494-023-01003-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-023-01003-5